Top 5 Trends in Heavy Equipment Manufacture You Need to Know in 2024

In 2024, the heavy equipment manufacturing industry is evolving faster than ever before. As global demands grow, manufacturers are turning to innovative technologies and processes to stay competitive. SSC Works, a leader in heavy equipment solutions, is at the forefront of these changes, offering custom manufacturing solutions that meet the unique needs of the industry. In this article, we’ll explore the top 5 trends in heavy equipment manufacture that are set to shape the future and how SSC Works is leading the charge in these advancements.

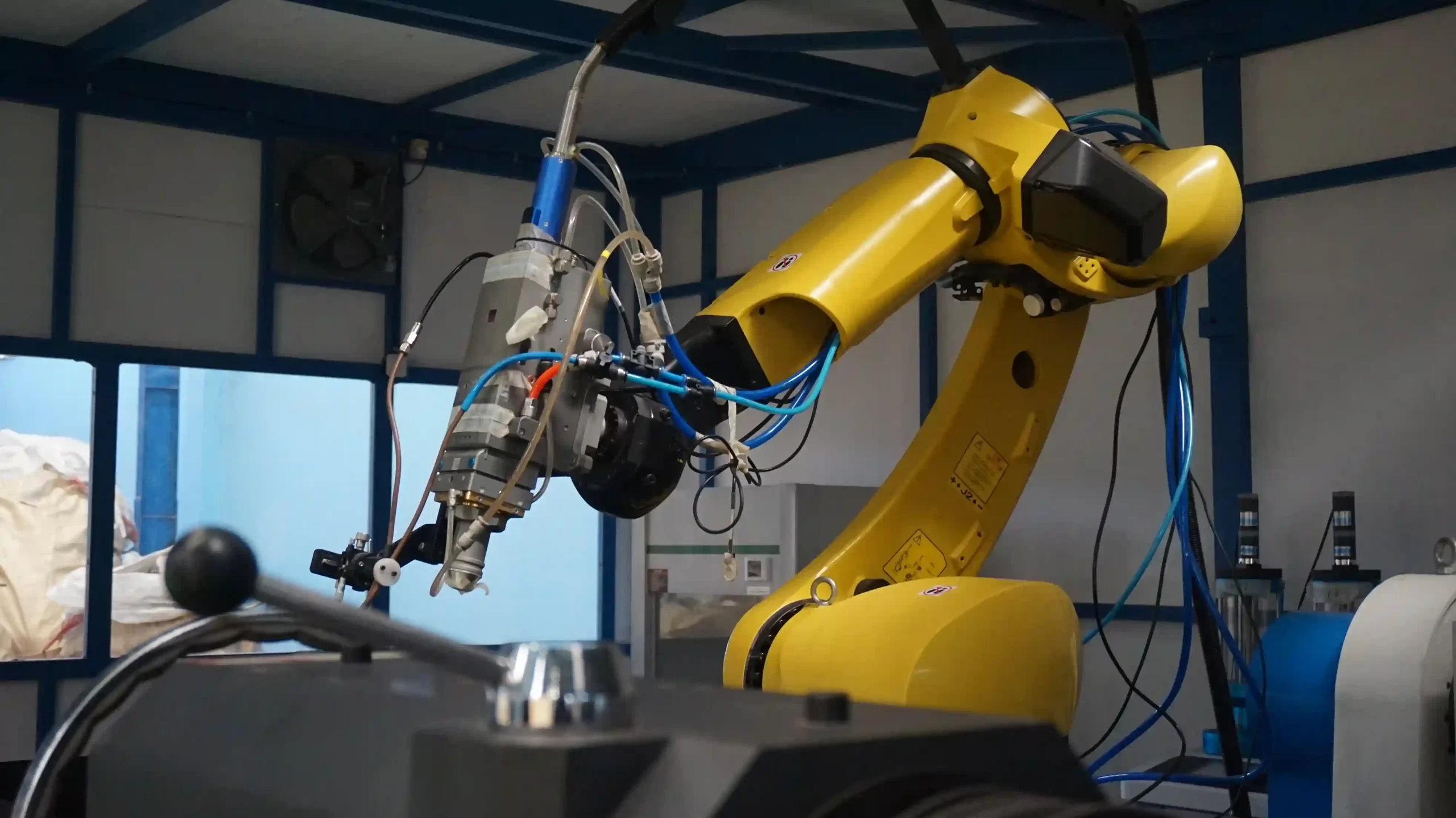

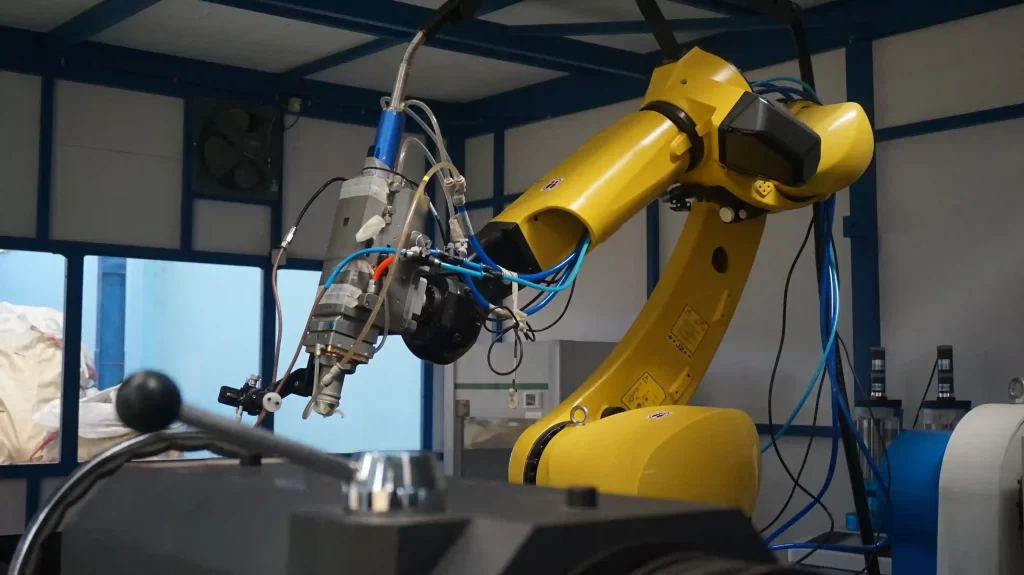

1. Advanced Automation and Robotics

The integration of advanced automation and robotics in heavy equipment manufacturing is revolutionizing the industry. From automated welding to robotic assembly lines, these technologies are improving efficiency, precision, and safety. SSC Works is leveraging these advancements to streamline production processes, reduce costs, and deliver high-quality custom components faster than ever before.

Is a company which undertakes its line of business in General Repair for heavy machinery, automotive, and industry.

2. Sustainable Manufacturing Practices

Sustainability is no longer just a buzzword; it’s a critical component of modern manufacturing. Companies are increasingly adopting eco-friendly materials and processes to reduce their carbon footprint. SSC Works is committed to sustainable manufacturing by implementing energy-efficient technologies and minimizing waste, ensuring that their operations are as green as possible.

3. Customization Through Additive Manufacturing

Additive manufacturing, or 3D printing, is transforming how custom parts are produced in the heavy equipment industry. This technology allows for the creation of complex components with precision and speed, reducing lead times and material waste. SSC Works utilizes additive manufacturing to offer highly customized solutions tailored to specific client needs, setting a new standard in the industry.

4. Integration of IoT in Manufacturing

The Internet of Things (IoT) is playing a crucial role in enhancing the manufacturing process. By connecting machines, tools, and systems, IoT enables real-time monitoring, predictive maintenance, and data-driven decision-making.

5. Enhanced Data Analytics for Quality Control

Data analytics is revolutionizing quality control in heavy equipment manufacturing. By analyzing data from production lines, manufacturers can identify defects, optimize processes, and ensure consistent product quality. SSC Works employs advanced data analytics to monitor every stage of production, ensuring that their custom components meet the highest standards of excellence.

The heavy equipment manufacturing industry is on the brink of a new era, driven by these emerging trends. To stay ahead of the curve, partnering with a company that understands and leverages these advancements is crucial. SSC Works is your trusted partner in delivering cutting-edge manufacturing solutions tailored to your needs. Contact us today to learn more about how we can help you achieve your goals in 2024 and beyond.