Fabrication is the Key to Heavy Equipment Repair

In the industrial world, repairing and maintaining heavy equipment is a major challenge that requires precise and timely solutions. One of the irreplaceable solutions is fabrication. But what exactly is fabrication?

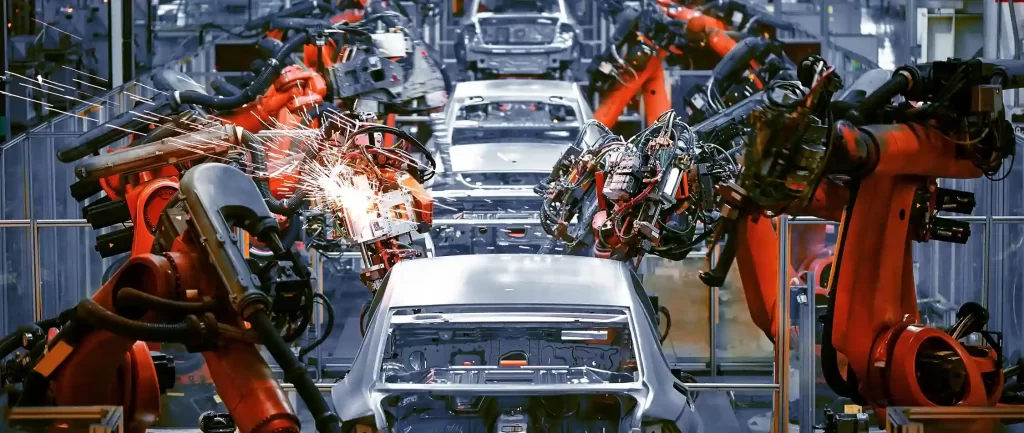

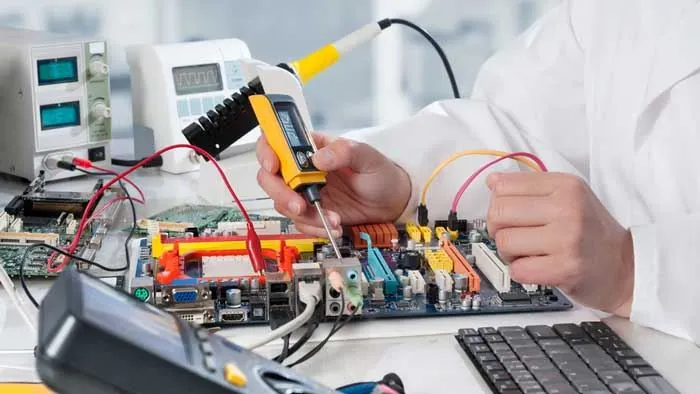

Fabrication is a manufacturing process that involves designing, cutting, and assembling raw materials into finished products. This process is crucial in the heavy equipment repair industry, as it enables the creation of custom components that are often unavailable in the market.

For example, locomotives, ships, and other heavy machinery often require specific parts that need to be customized to meet specific needs. Fabrication allows the creation of these components with a high level of accuracy, whether for individual repairs, bulk orders, or mass production.

As a professional in this field, I’ve witnessed firsthand how a major project was delayed due to the unavailability of the right replacement parts. Through fabrication, we were able to produce the necessary components with precise specifications, saving the project from costly delays.

Fabrication also allows for innovation and increased efficiency in heavy machinery. For example, by repairing or modifying existing machinery, productivity can be enhanced without the need to purchase new, more expensive equipment.

SSC Works, with its expertise in fabrication, offers reliable services for repairing and creating custom components. We ensure that every component manufactured meets the highest quality standards, so your heavy equipment can get back to optimal operation.

If you’re facing issues with heavy equipment or need custom components, trust SSC Works to meet your needs. We are ready to assist you at every stage of repair and maintenance, from fabrication to installation.