Maintenance is the Key to Heavy Equipment Reliability

Maintenance is a periodic process conducted to ensure that machines and equipment continue to function properly.

In the heavy machinery industry, maintaining optimal performance of machines and equipment is essential. One of the best ways to ensure this is through regular maintenance. At SSC Works, we believe that maintenance is not just a preventive measure but a long-term investment in reliability and operational efficiency.

Maintenance: Definition and Benefits

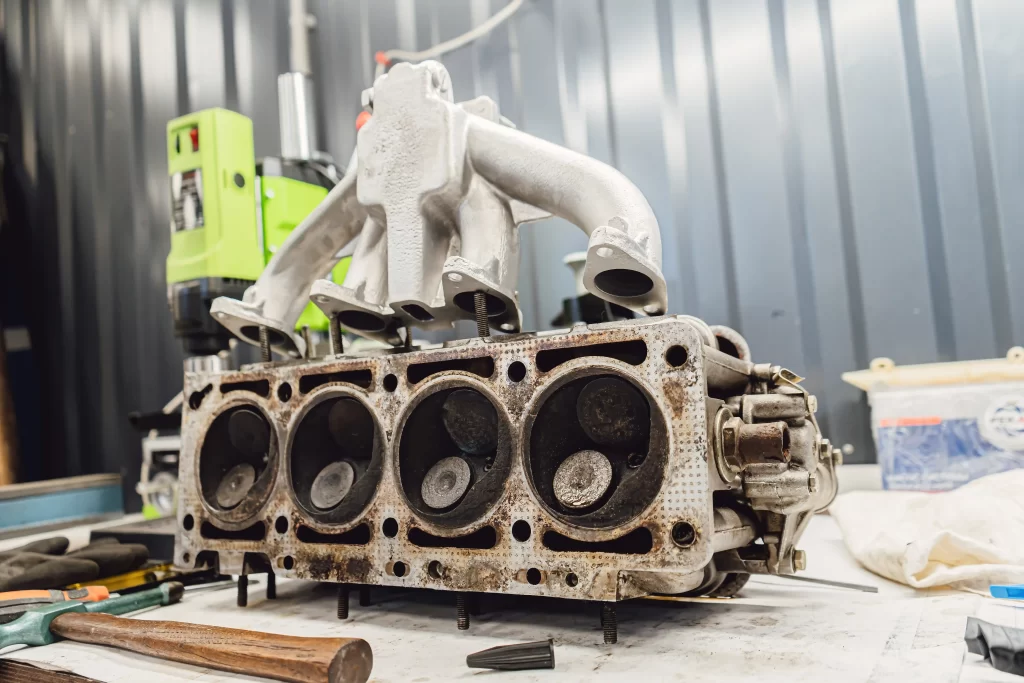

Maintenance is a periodic process conducted to ensure that machines and equipment continue to function properly. This process includes inspections, repairs, replacement of worn parts, and cleaning of components. By performing maintenance, you can prevent more severe damage and avoid costly repairs.

In the context of heavy equipment, maintenance plays a crucial role. Machines operating in harsh environments like mining or construction often face high pressure, vibrations, and extreme weather conditions. Without proper maintenance, these machines can suffer significant damage, ultimately disrupting operations and causing substantial losses.

Types of Maintenance in Heavy Equipment

There are several types of maintenance commonly performed on heavy equipment, including:

Preventive Maintenance: This is routine maintenance conducted on a scheduled basis, such as changing engine oil, checking tire conditions, or cleaning air filters. The goal is to prevent damage before it occurs.

Predictive Maintenance: Utilizes technology and data to predict when a component might fail. For example, using sensors to monitor vibrations or temperature in the machinery.

Corrective Maintenance: Maintenance performed after damage has occurred. This includes repairing or replacing damaged components.

Condition-Based Maintenance: Maintenance based on the actual condition of the machine or component, such as measuring wear levels or observing performance changes.

.

SSC Works’ Commitment to Heavy Equipment Maintenance

At SSC Works, we provide comprehensive maintenance services tailored to the specific needs of each client. Supported by experienced technicians and advanced tools, we can perform maintenance on various types of heavy equipment, including excavators, dump trucks, and other industrial machines.

We also offer custom maintenance services, where the maintenance schedule and procedures are adapted to the operational conditions and specific needs of your machinery. With this approach, we ensure that your heavy equipment is always in prime condition and ready for use at any time.

Maintenance is the key to maintaining the performance and reliability of heavy equipment. By performing maintenance regularly and consistently, you not only extend the life of the machinery but also ensure efficient and safe operations. SSC Works is ready to be your trusted partner in providing high-quality maintenance services for all types of heavy equipment.