Crankshaft in Heavy Machinery: Essential for Optimal Performance

The crankshaft is a component within an engine that converts the up-and-down motion of the pistons into rotational motion, which then drives the wheels or other components in heavy machinery.

In the world of heavy machinery and mining vehicles, the crankshaft is one of the key components that determine engine performance and efficiency. SSC Works fully understands the importance of a precision-engineered crankshaft to ensure that heavy machinery operates effectively in the field. This article will explore what a crankshaft is, its role in heavy machinery and mining vehicles, and how proper maintenance can maintain engine reliability.

What is a Crankshaft?

The crankshaft is a component within an engine that converts the up-and-down motion of the pistons into rotational motion, which then drives the wheels or other components in heavy machinery. Made from highly durable materials like forged steel, the crankshaft must withstand immense pressure and loads, especially under the extreme working conditions commonly found in the mining industry.

In heavy machinery and mining vehicles, the crankshaft must be highly precise, as even a slight misalignment can lead to excessive vibration, reduced efficiency, and potentially severe engine damage.

Crankshaft’s Role in Heavy Machinery and Mining Vehicles

In the context of heavy machinery and mining vehicles, the crankshaft plays a crucial role. These machines often operate under extremely harsh conditions, such as high temperatures, rugged terrain, and intense workloads found in mining environments. Therefore, a precise and durable crankshaft is essential to ensure that the engine operates with high efficiency and minimal disruptions.

The crankshaft is also key to maintaining engine balance. If the crankshaft is not precise, it can cause imbalance, leading to premature wear on other engine components, increasing the risk of breakdowns and repair costs.

Crankshaft Maintenance and Repair at SSC Works

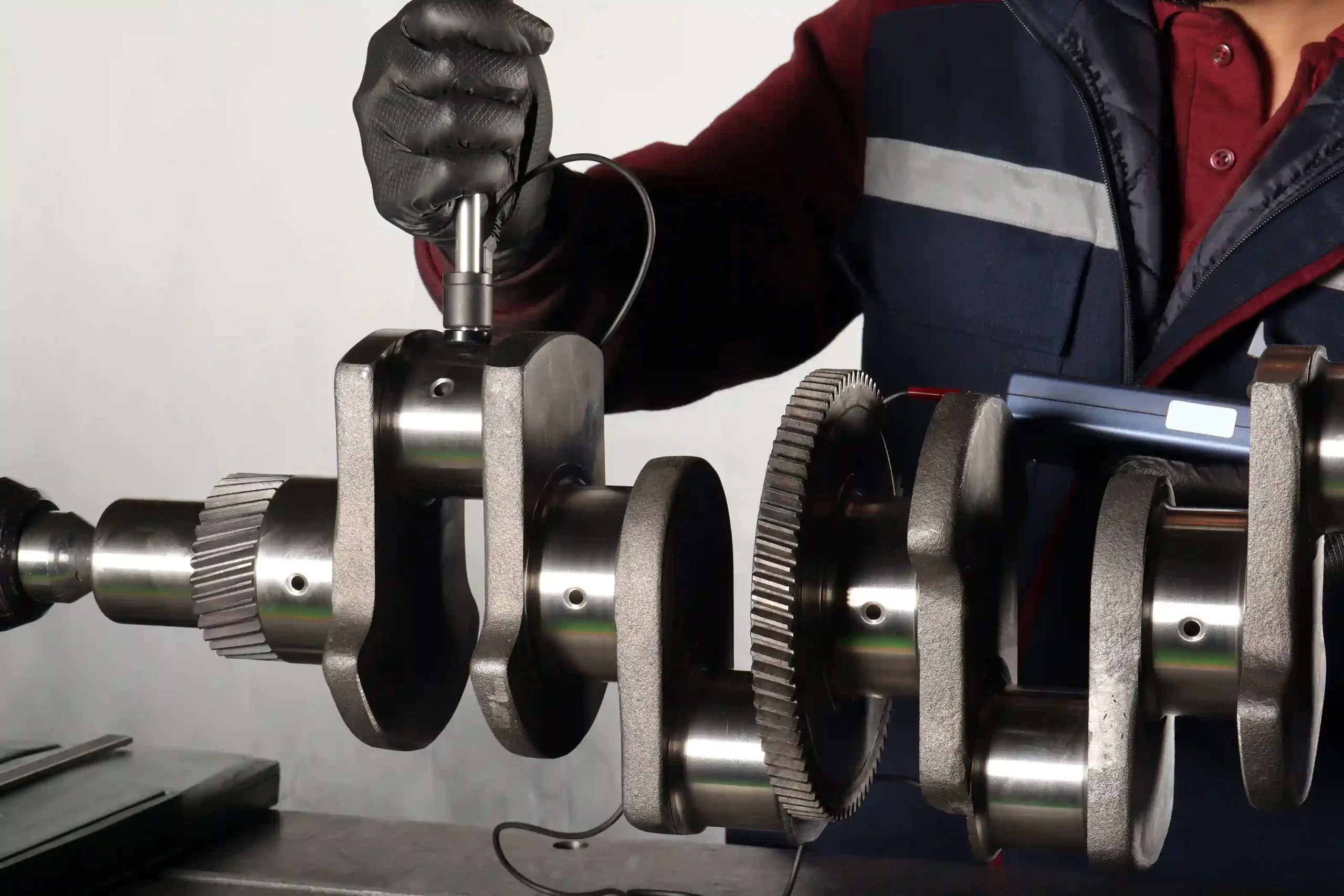

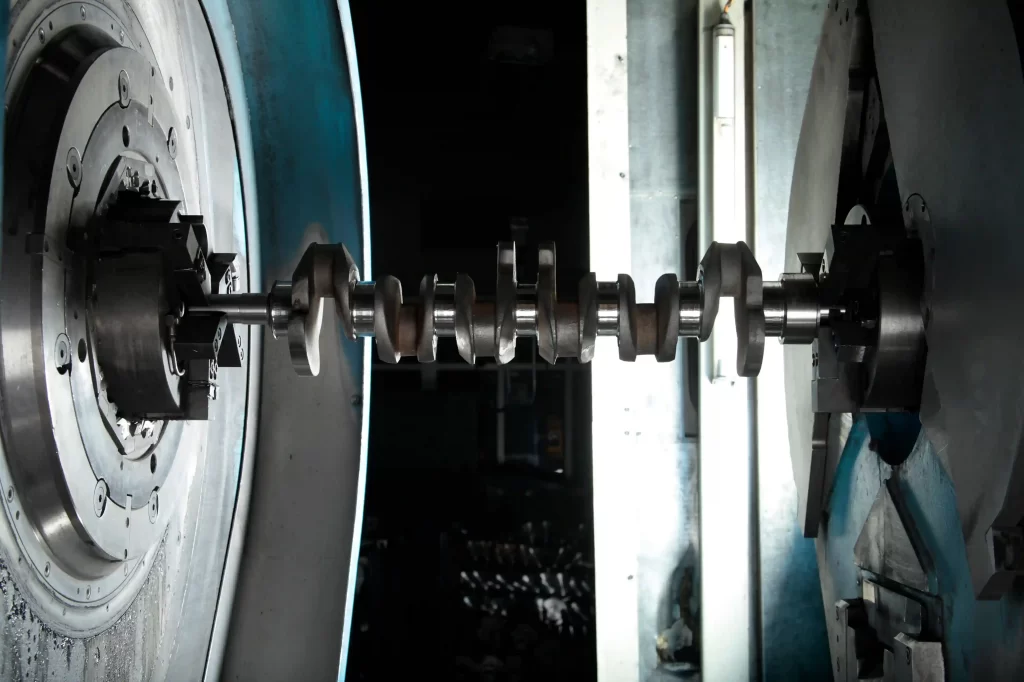

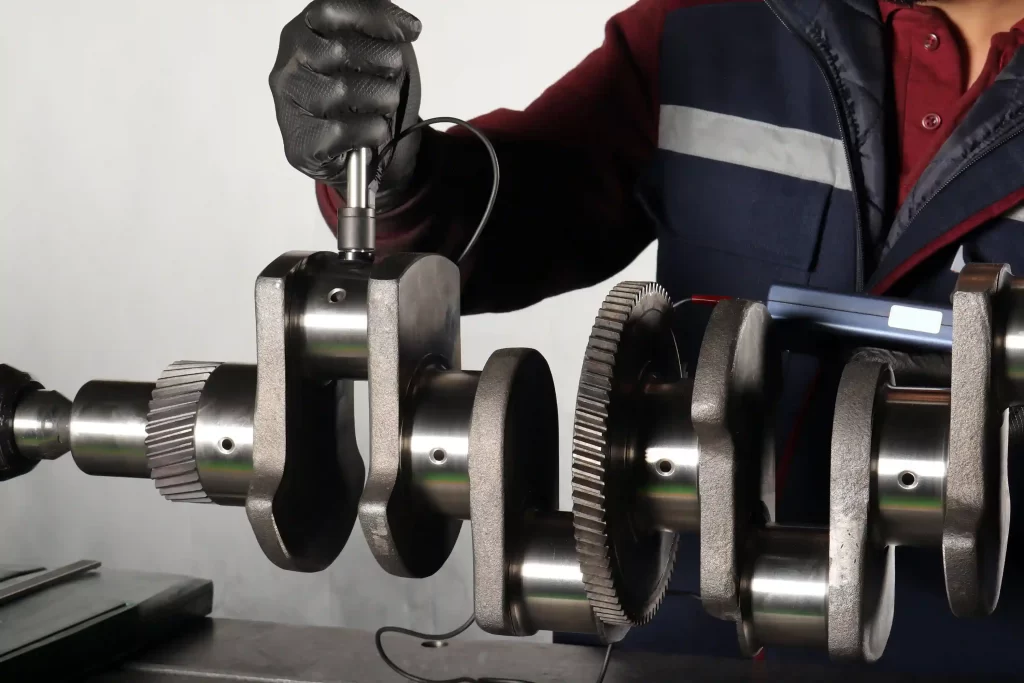

At SSC Works, we offer specialized maintenance and repair services for crankshafts designed for heavy machinery and mining vehicles. Our services include thorough inspections, precision measurements, repair or replacement of worn parts, and testing to ensure that the crankshaft functions perfectly.

We understand that the crankshaft is one of the most critical components in the engine, so proper maintenance is vital. Our services also include precision repairs using advanced machinery to ensure that your crankshaft returns to optimal condition, ready to withstand tough working conditions.

SSC Works’ Expertise in Crankshaft Handling

SSC Works has extensive experience in handling various types of crankshafts for heavy machinery and mining vehicles. With a team of experienced technicians and modern equipment, we can provide precise and reliable repair and maintenance services.

In addition to repairs, we also offer customization services for crankshafts, tailored to your machine’s specific needs. With this service, you can be confident that your crankshaft will function optimally and your engine will operate smoothly without issues.

The crankshaft is the heart of every heavy machinery engine and mining vehicle. Keeping this component in prime condition is key to ensuring that the engine operates with maximum efficiency and high reliability. With precision maintenance and repair services from SSC Works, your crankshaft will remain in top condition, ensuring that your machine can perform under even the most challenging conditions.