5R is a Key to Successful Heavy Machinery Maintenance

5R is an acronym for five Japanese words, each representing a critical aspect of efficient workplace management

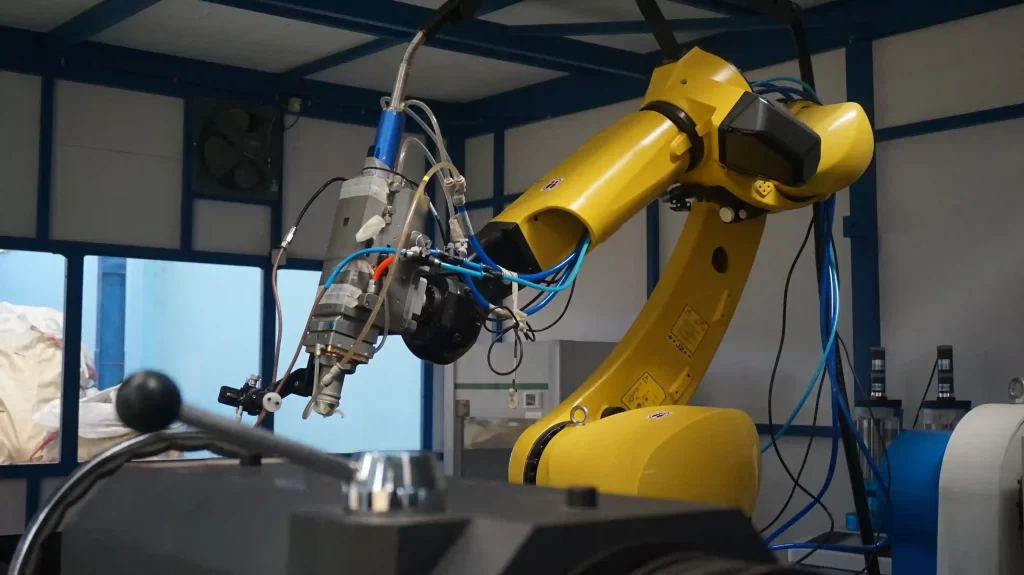

In the heavy machinery industry, efficiency and safety are top priorities. One of the most important methods for achieving these goals is the implementation of the 5R concept. 5R is an approach originating from Japan that has proven effective in maintaining cleanliness, organization, and operational efficiency in the workplace. At SSC Works, we integrate the principles of 5R in every aspect of heavy machinery maintenance and repair to ensure your equipment remains in optimal condition. In this article, we will discuss what 5R is, how it is applied, and its benefits for heavy machinery maintenance.

What is 5R?

5R is an acronym for five Japanese words, each representing a critical aspect of efficient workplace management:

Seiri (Sort): Separate unnecessary items and discard them. In the context of heavy machinery maintenance, this means managing inventory of spare parts and tools effectively, keeping only what is truly needed.

Seiton (Set in Order): Arrange necessary items in an orderly manner so they are easy to find and use. This includes logically organizing tools and spare parts.

Seiso (Shine): Maintain a clean work environment. Regular cleaning of heavy machinery and work areas ensures that no issues are overlooked due to dirt or dust.

Seiketsu (Standardize): Maintain the cleanliness and organization achieved through Seiri, Seiton, and Seiso. This means ensuring all heavy machinery is regularly maintained according to established procedures.

Shitsuke (Sustain): Discipline yourself to consistently apply the first four principles. This is the step that ensures 5R becomes a part of everyday work culture.

Application of 5R in Heavy Machinery Maintenance

At SSC Works, the application of 5R focuses not only on workplace efficiency but also on comprehensive heavy machinery maintenance. Here’s how each element of 5R is applied in heavy machinery maintenance:

Seiri: At SSC Works, we ensure that only the necessary spare parts and tools for heavy machinery maintenance are kept. A tidy inventory helps avoid storing unnecessary items that can take up space and make searching more difficult.

Seiton: Tools and spare parts are neatly arranged and clearly labeled for easy access. This saves time when our technicians need to perform quick maintenance or repairs.

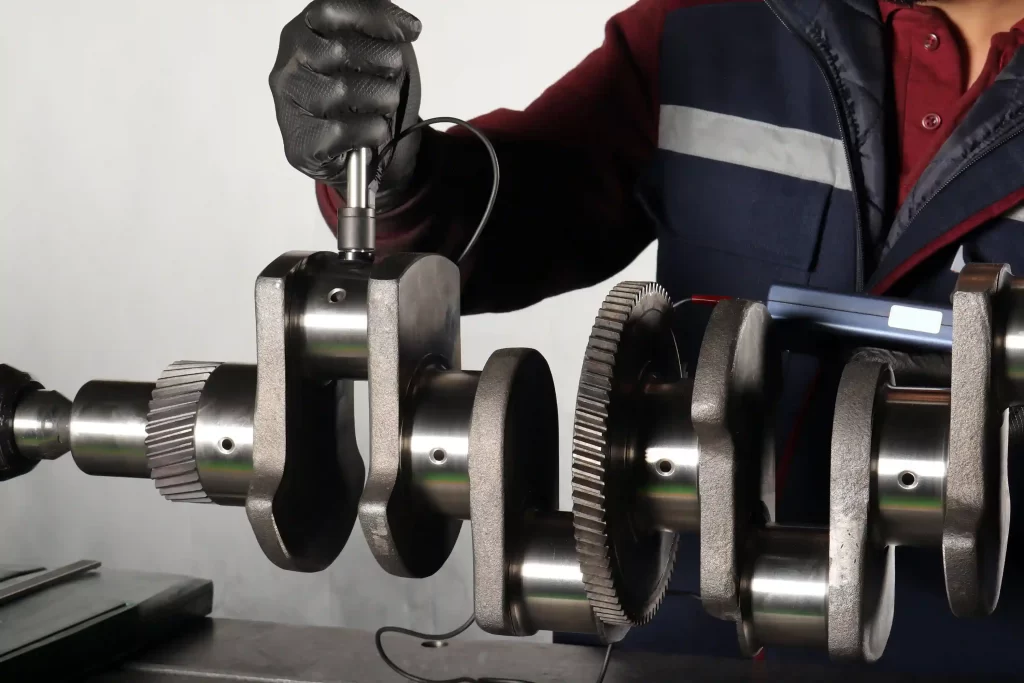

Seiso: Cleaning heavy machinery is an essential part of maintenance at SSC Works. Each piece of equipment is routinely cleaned to prevent dirt buildup that can cause component failure.

Seiketsu: We ensure that the maintenance standards for heavy machinery at SSC Works are always high. Every maintenance process is carried out according to set standards, ensuring your heavy machinery always operates at its best.

Shitsuke: At SSC Works, discipline in applying 5R is the key to success. We ensure that every technician understands and applies the principles of 5R in every aspect of their work.

Benefits of 5R in Heavy Machinery Maintenance

By consistently applying the principles of 5R, SSC Works can provide more efficient, faster, and safer heavy machinery maintenance and repair services. Some of the key benefits include:

- Time Efficiency: A well-organized work process reduces the time spent searching for tools or spare parts, allowing maintenance to be completed faster.

- Higher Safety: A clean and tidy work environment reduces the risk of accidents caused by clutter or improper use of equipment.

- Better Maintenance Quality: By maintaining high cleanliness and organization standards, the quality of heavy machinery maintenance also improves, meaning your machinery will last longer and perform better.

5R is an essential method for maintaining efficiency and safety in the workplace, especially in heavy machinery maintenance. SSC Works proudly applies the principles of 5R to ensure your equipment receives the best care possible, enhancing its performance and longevity. If you want to ensure your heavy machinery is always in top condition, trust its maintenance to SSC Works, where 5R is part of every maintenance step we take.