Milling Machines: Essential Tools in Heavy Equipment Repair

milling machine is a tool used to cut and shape materials with high precision. The milling process involves using a rotating cutter mounted on the machine’s spindle, which is then used to cut the material into the desired shape.

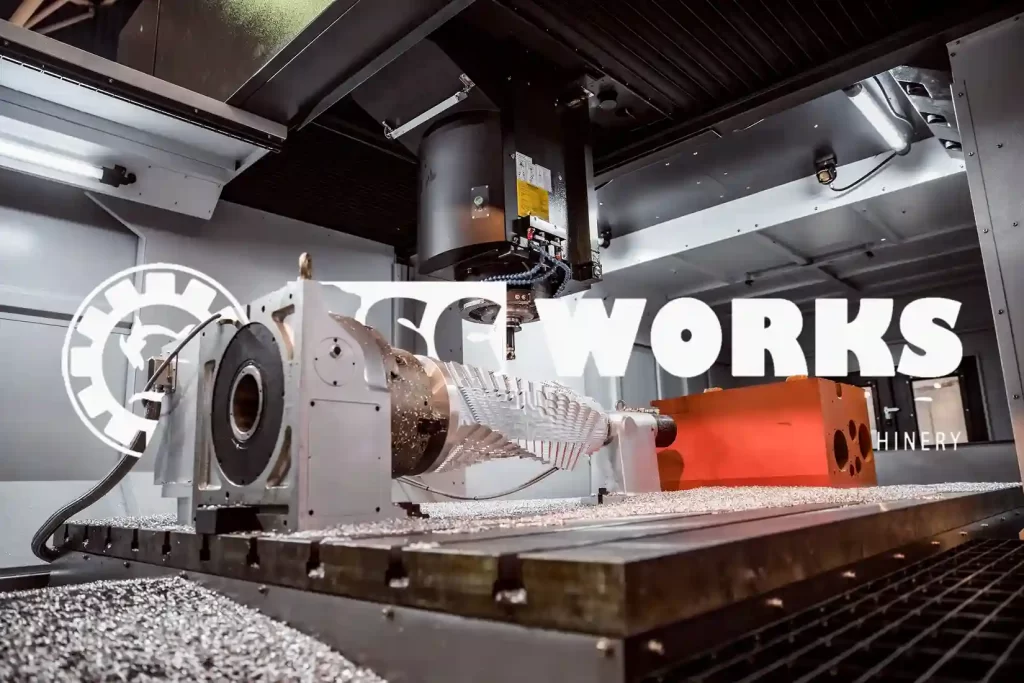

In the world of heavy machinery repair and component manufacturing, precision and efficiency are paramount. One of the essential tools for achieving this precision is the milling machine. A milling machine is a machine tool used for cutting and shaping materials, primarily metal, using a rotating cutter. At SSC Works, milling machines play a crucial role in the repair and fabrication of custom components that meet the highest quality standards. This article will discuss what a milling machine is, the different types, and how milling machines are used in the heavy equipment industry.

What is a Milling Machine?

A milling machine is a tool used to cut and shape materials with high precision. The milling process involves using a rotating cutter mounted on the machine’s spindle, which is then used to cut the material into the desired shape. This process can create various complex shapes and surfaces, which are essential in the fabrication of heavy machinery components.

Types of Milling Machines

There are several types of milling machines commonly used in the heavy machinery industry, including:

Horizontal Milling Machines: These machines have a spindle that is parallel to the machine table. Horizontal milling machines are ideal for cutting hard and thick materials, as well as for tasks requiring substantial power.

Vertical Milling Machines: In these machines, the spindle stands perpendicular to the machine table. Vertical milling machines are often used for tasks requiring high precision and are relatively easy to operate.

CNC Milling Machines: Computer Numerical Control (CNC) milling machines are controlled by a computer, offering extremely high precision and the ability to perform various tasks automatically.

Universal Milling Machines: These machines can function as both horizontal and vertical milling machines, making them versatile and suitable for a wide range of tasks.

The Importance of Milling Machines in the Heavy Equipment Industry

At SSC Works, milling machines are extensively used in the repair and manufacturing of heavy equipment components. Here are some reasons why milling machines are so important:

Precision Component Fabrication: Heavy machinery components often require very tight tolerances. Milling machines allow for the fabrication of components with high precision, ensuring that each part meets the required specifications.

Custom Component Repair: When standard components are no longer adequate or available, milling machines allow for the creation of custom components that meet the specific needs of your heavy equipment.

Production Efficiency: With milling machines, the component manufacturing process can be completed quickly and efficiently, reducing equipment downtime and increasing productivity.

High Quality: The use of milling machines at SSC Works ensures that every component produced is of superior quality, allowing heavy machinery to operate safely and efficiently.

Milling machines are essential tools in the heavy machinery repair and component manufacturing industry. At SSC Works, we prioritize precision and efficiency in every task we undertake. With advanced equipment and experienced technicians, we are ready to provide the best services to meet your heavy equipment repair and component fabrication needs. Trust SSC Works to keep your equipment in optimal condition because milling machines are the key to quality and durability.