Caterpillar Spindle: Function, Uses, and Maintenance

The Caterpillar spindle is a crucial component in the machinery of heavy equipment, particularly for Caterpillar brand machines. This component plays a vital role in ensuring the optimal performance of the machine, especially in applications involving high-precision rotation and movement. Understanding the function, uses, and maintenance of the Caterpillar spindle is key to keeping your heavy equipment in peak condition.

Function of Caterpillar Spindle

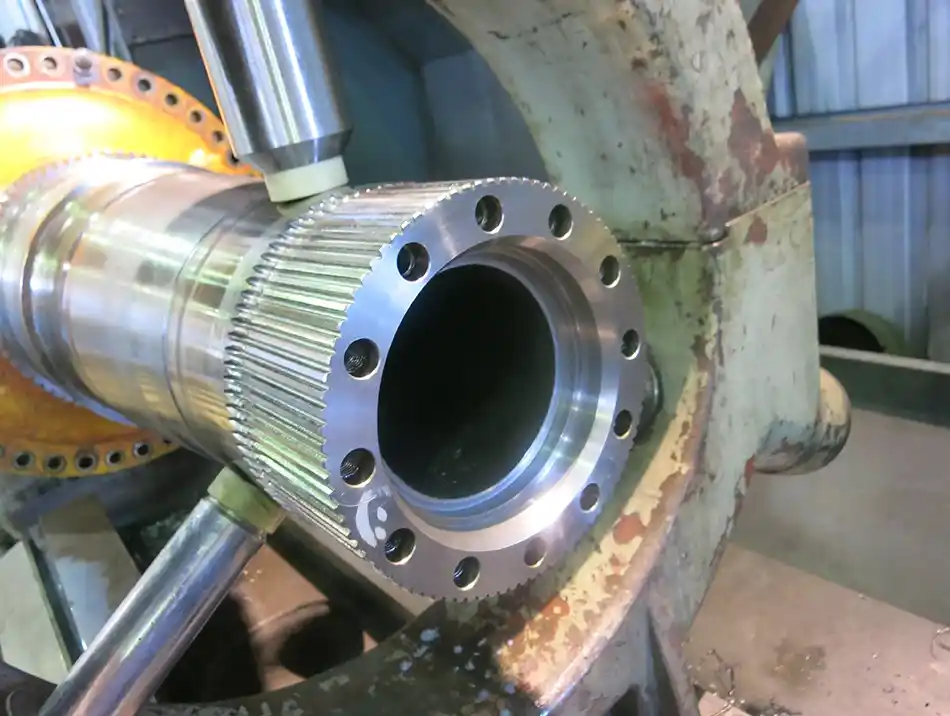

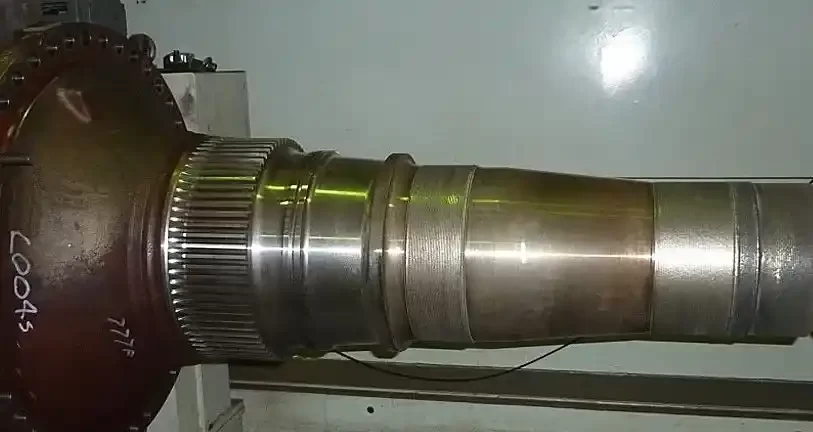

The spindle in Caterpillar machines serves as the shaft that supports the rotation of various machine components. It is essential in ensuring that all rotating parts operate harmoniously and efficiently. The primary functions of the Caterpillar spindle include:

Transmission of Rotational Motion: The spindle enables the transfer of rotational motion from the motor to other components, such as wheels or cutting tools, necessary for the operation of heavy equipment.

Stabilization of Rotating Components: The spindle also helps stabilize rotating components, ensuring they remain balanced and do not experience excessive vibrations that could lead to damage.

Application of Force to Other Components: In addition to transmitting motion, the spindle also serves to apply certain forces to other components, such as in drilling or cutting processes.

Uses of Caterpillar Spindle

The spindle in Caterpillar heavy equipment is used in various applications, including:

Cutting and Drilling Operations: In heavy equipment equipped with cutting or drilling functions, the spindle is a key component that allows these tools to work with precision.

Load Lifting: The spindle can also be used in load-lifting mechanisms, ensuring that heavy equipment can safely and efficiently lift and move materials.

Machine Rotation Control: In drive systems, the spindle plays a critical role in controlling the speed and direction of rotation, which is essential for precision operations.

Maintenance of Caterpillar Spindle

To ensure that the Caterpillar spindle remains in optimal condition, routine maintenance is essential. Here are some maintenance steps that can be performed:

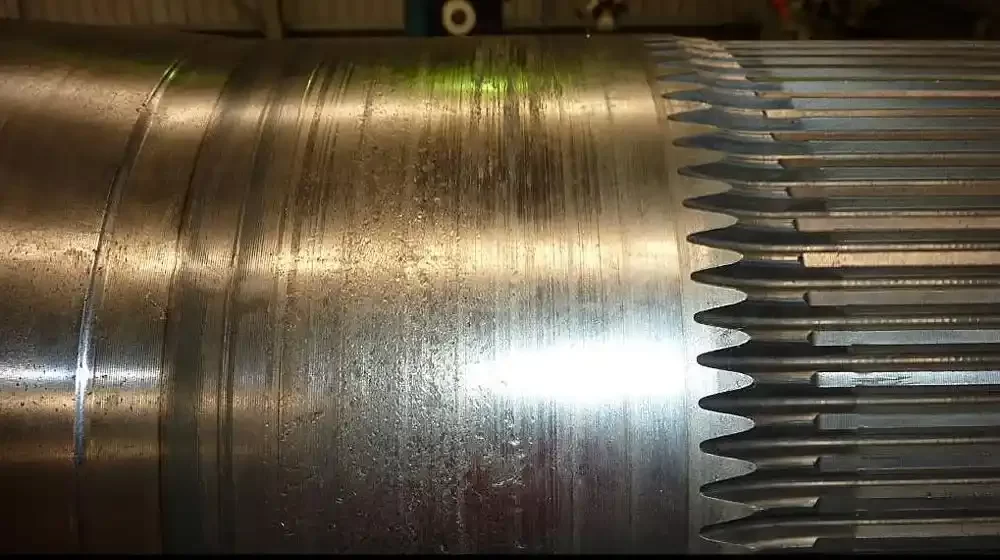

Regular Lubrication: Ensure the spindle is regularly lubricated with the appropriate lubricant to prevent wear and overheating.

Damage Inspection: Regularly inspect the spindle for signs of wear, cracks, or other damage. Replace it immediately if damage is found to prevent further issues.

Periodic Recalibration: The spindle should be periodically recalibrated to ensure it continues to operate with precision. Improper calibration can lead to inaccuracies in machine operations.

Regular Cleaning: Clean the spindle and surrounding areas of dirt, dust, and other particles that could interfere with its performance.

Conclusion

The Caterpillar spindle plays a crucial role in the operation of heavy equipment, with functions involving motion transmission, component stabilization, and force application. With a good understanding of its functions and uses, along with proper maintenance, you can ensure that your Caterpillar heavy equipment operates efficiently and has a long service life. SSC Works is ready to assist you in the maintenance and repair of Caterpillar spindles, ensuring your heavy equipment’s performance is always at its best.