Differential Housing Caterpillar: Definition, Functions, Types, and Maintenance

The differential housing Caterpillar is a crucial component found in the drivetrain system of heavy equipment, particularly in Caterpillar vehicles. This component plays an essential role in protecting the internal differential components and supporting the movement of heavy equipment across challenging terrains. Understanding the definition, functions, types, and maintenance of the differential housing is key to ensuring your Caterpillar equipment operates efficiently.

Definition of Differential Housing Caterpillar

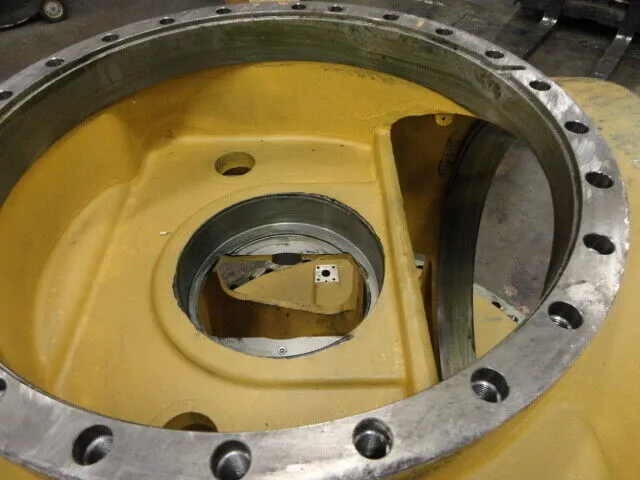

The differential housing is a protective casing that houses the differential mechanism inside. The differential itself distributes power from the engine to the wheels, allowing the wheels to rotate at different speeds, especially when turning or navigating uneven terrain. The differential housing protects the internal components from damage caused by dust, dirt, water, or impact during operation.

Functions of Differential Housing Caterpillar

The primary functions of the differential housing Caterpillar include:

Protection of Internal Components: The main function of the differential housing is to protect the differential and other internal parts from contamination by dust, water, or dirt, which can cause wear or damage.

Structural Support for the Drivetrain: The differential housing also acts as a structural component that supports and stabilizes the drivetrain during the operation of heavy equipment.

Maintaining Operational Stability: By protecting the internal components from damage, the differential housing helps ensure the stability and performance of heavy equipment, particularly when navigating challenging terrains or during complex maneuvers.

Types of Differential Housing Caterpillar

There are several types of differential housing Caterpillar used in heavy equipment, depending on the type of vehicle and its application. Some of the most common types include:

Cast Iron Differential Housing: Made from strong cast iron, this housing is typically used in heavy equipment that operates in harsh terrains and demands high durability.

Aluminum Differential Housing: Made from aluminum, this type of housing is lighter and is often used in vehicles that require weight reduction without sacrificing structural strength.

Heavy-Duty Differential Housing: Used in heavy-duty equipment with high workloads, this housing is designed to withstand heavy loads and maintain drivetrain stability during extreme operating conditions.

Maintenance of Differential Housing Caterpillar

To ensure the differential housing remains in optimal condition, regular maintenance is essential. Here are some maintenance steps that can be performed:

Visual Inspection: Regularly perform a visual inspection of the differential housing to detect cracks, oil leaks, or other physical damage that could affect the component’s performance.

Oil Replacement: Ensure to replace the differential oil periodically. The oil helps lubricate the internal differential components, and regular replacement will prevent wear and extend the differential’s lifespan.

Housing Cleaning: Clean the housing of mud, dust, or dirt that may accumulate around the component, especially if the heavy equipment is used in harsh environments like mining or construction sites.

Seal and Bolt Inspection: Ensure that all seals and bolts on the differential housing are in good condition and properly tightened to prevent leaks and maintain the system’s stability.

Conclusion

The differential housing Caterpillar plays a critical role in protecting the differential and drivetrain components from damage and ensuring the operational stability of heavy equipment. With a clear understanding of its definition, functions, types, and proper maintenance, you can ensure that your Caterpillar heavy equipment continues to operate efficiently and has a longer lifespan. SSC Works is ready to assist you in the maintenance and repair of Caterpillar differential housing to keep your heavy equipment performing at its best.