Crack Repair: Definition, Types, and Proper Handling

In the heavy equipment industry, cracks in machinery components are not uncommon, especially when operating in demanding conditions. Crack repair becomes crucial to ensure the machinery’s continued performance and safety. My field experience has shown that failure to address cracks can lead to significant downtime and even catastrophic failure. In this article, we’ll explore crack repair, including its definition, types, and the proper methods for addressing it.

Definition of Crack Repair

Crack repair is the process of fixing fractures or cracks in machinery components to restore their structural integrity and functionality. Cracks in heavy machinery can be caused by a variety of factors, such as overloading, material fatigue, or accidents in the field. If left unaddressed, these cracks can grow larger, leading to more serious damage and potential machinery failure.

Common Types of Cracks

During my time working in the field, I’ve encountered various types of cracks in heavy machinery, each requiring specific handling. Here are some of the most common types:

- Fatigue Cracks: These occur due to long-term use without proper maintenance. Components like pistons, crankshafts, or engine blocks are particularly susceptible to fatigue cracks.

- Thermal Cracks: Caused by extreme temperature changes, such as rapid heating or cooling. I once encountered a thermal crack in a large genset that overheated due to a malfunctioning cooling system.

- Structural Cracks: Typically found in the framework or chassis of heavy machinery caused by impact or excessive load, particularly in mining trucks or excavators.

- Corrosion Cracks: Develop over time due to chemical reactions between the material and environmental elements, such as exposure to water or chemicals in mining or industrial sites.

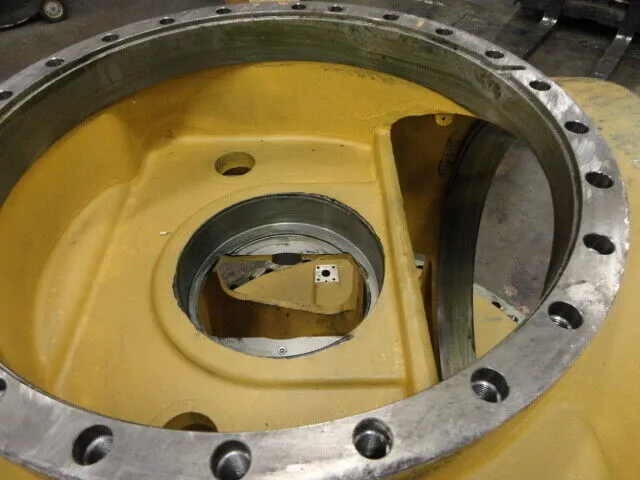

Crack Repair Methods and Techniques

Several methods are used to repair cracks in heavy machinery. Based on my field experience, the following are some of the most common techniques:

Welding: Welding is the most common method for fixing cracks. It involves melting metal and filling the crack, then sealing it back together. This method is frequently used for repairing cracks in machinery frames.

Metal Stitching: This technique is suitable for repairing cracks in materials that cannot be welded, such as cast iron engine blocks. Metal stitching uses specialized pins or bolts to close and strengthen the crack without generating excessive heat.

Overlay Welding: Overlay welding involves adding a new layer of metal over the cracked surface. This technique strengthens the component and prevents future cracks in the same area.

Cold Welding: Cold welding is a repair technique that doesn’t involve heat. It’s useful for materials sensitive to temperature, like aluminum. I’ve seen this technique used on aircraft and ship components.

Epoxy Injection: This non-destructive method is often used for minor cracks or micro-cracks, where epoxy resin is injected into the crack to fill and reinforce the material’s structure.

Common Incidents in the Field

In the field, various incidents can lead to cracks or even serious accidents if not promptly addressed. From my experience, the following are common occurrences:

Overloading Heavy Machinery: Exceeding the load capacity of machinery often leads to cracks in components such as the frame or chassis. This is especially common in mining operations where machines work under extreme conditions.

Cooling System Failure: In heavy machinery like gensets or ship engines, cooling system failures can cause overheating, leading to thermal cracks in the engine block or cylinder head.

Hard Impact During Operation: I once dealt with a situation where a piece of heavy machinery collided with a mine wall or a large boulder, causing structural cracks in the excavator. If such impacts are not immediately inspected and repaired, they could lead to total machine failure.

Corrosion Exposure in Mining Environments: Harsh environments, such as mines, often contain chemicals or high moisture levels that lead to corrosion. Over time, this corrosion weakens components and causes cracks in vital parts.

Importance of Regular Inspection and Maintenance

As I’ve learned in the field, crack repair is most effective when carried out before cracks become severe. Regular inspection and preventive maintenance are essential to ensure there are no hidden cracks that could develop into major issues. SSC Works provides comprehensive inspection and heavy machinery repair services, from welding to component replacement, ensuring your operations run smoothly.