Engine Overhaul: Definition, Types, and Repair Procedure

When heavy machinery engines start showing signs of performance degradation, one of the most common solutions is an engine overhaul. Having been involved in the overhaul process firsthand, I understand how crucial this procedure is for extending the engine’s lifespan and maintaining its efficiency. In this article, we will explore the definition of engine overhaul, its types, and the common repair procedures performed in the heavy machinery industry.

Definition of Engine Overhaul

An engine overhaul is a comprehensive repair process in which the engine’s internal components are inspected, cleaned, replaced, or repaired as needed. Overhauls are performed when the engine experiences significant performance drops due to wear and tear, but it’s still possible to restore the engine. It is a more cost-effective solution than replacing the entire engine.

From my experience in the field, overhauls are often necessary when engines become difficult to start, lose power, or consume excessive fuel. If not addressed promptly, the engine could suffer further damage, leading to complete failure.

Types of Engine Overhaul

In the heavy machinery industry, engine overhauls are categorized into several types, depending on the severity of the engine’s condition and the required repairs:

Minor Overhaul: This type involves repairing minor components without disassembling the entire engine. Minor overhauls are typically done when the engine exhibits light issues, such as unusual noise or a slight loss of power. The process includes cleaning, oil changes, filter replacement, and inspection of key components like spark plugs or fuel injectors.

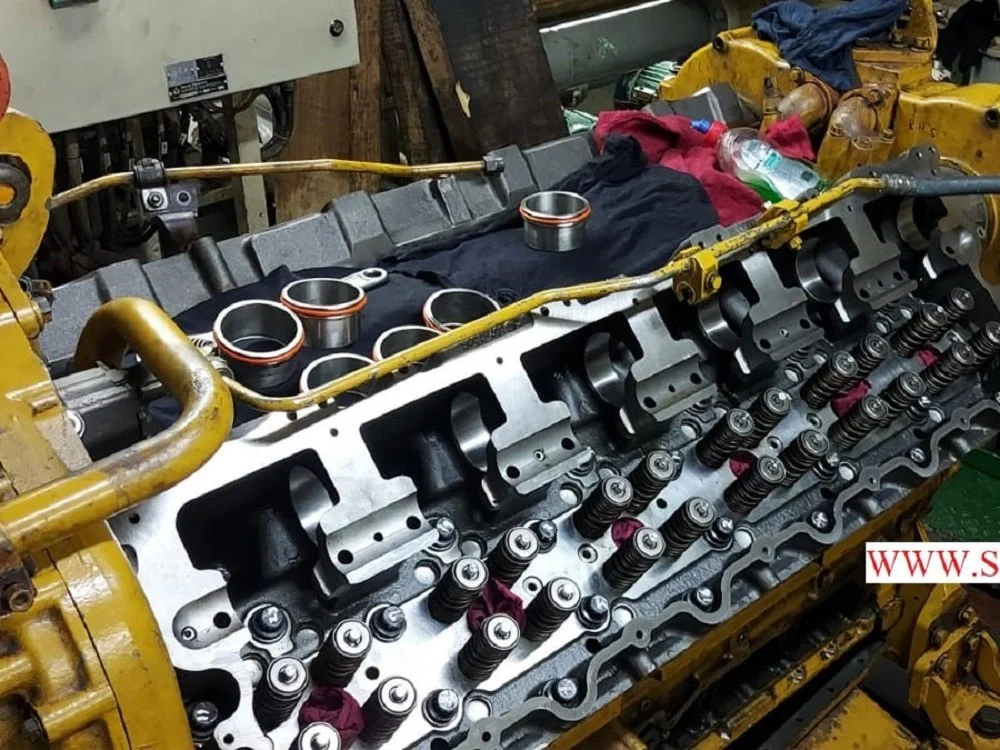

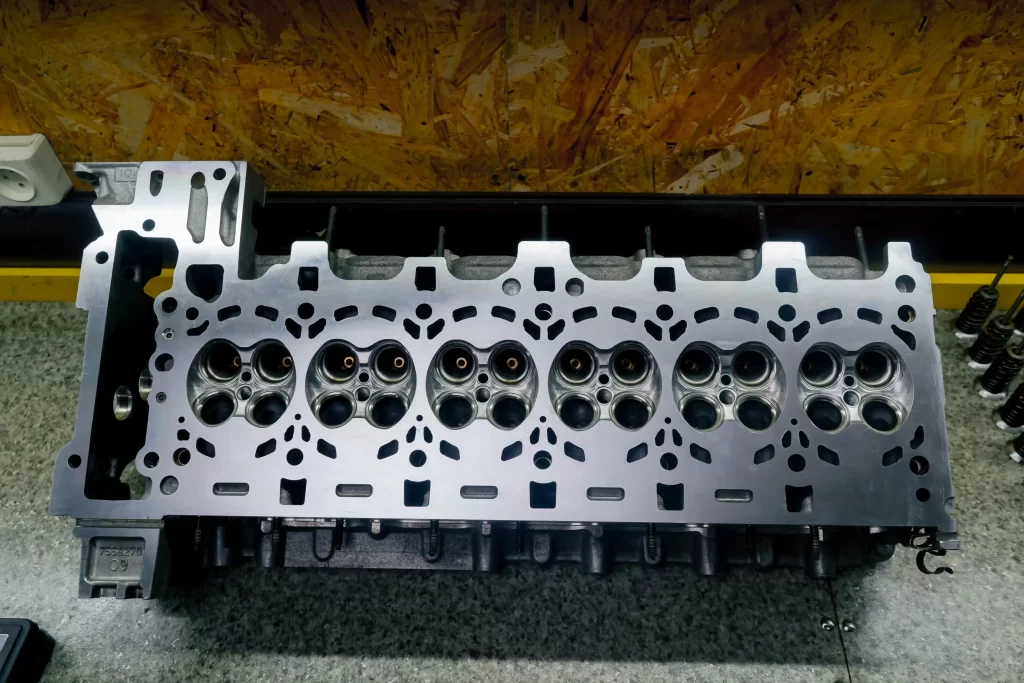

Top Overhaul: In a top overhaul, repairs are focused on the upper part of the engine, including the cylinder head, valves, pistons, and combustion system. I’ve personally conducted a top overhaul on a genset engine that frequently overheated due to worn-out valves and a faulty cylinder head.

Major Overhaul (Full Overhaul): This is a complete repair that involves disassembling the entire engine, replacing or repairing critical components like the crankshaft, pistons, and engine block. A major overhaul is necessary when the engine has suffered significant damage or performance degradation.

Engine Overhaul Procedure

While overhaul procedures vary based on the type of engine and the extent of the damage, the following are general steps commonly followed during engine overhauls based on my field experience:

Initial Diagnosis: The first step is to conduct a thorough inspection of the engine to identify the main issues. This involves compression testing, checking for oil leaks, and analyzing engine noise.

Engine Disassembly: After identifying the problems, the engine is disassembled to inspect its internal components. Key parts like the pistons, crankshaft, camshaft, and valves are removed and checked for wear or damage.

Component Cleaning: Components that are not damaged are carefully cleaned to remove accumulated dirt and deposits. From my experience, keeping components clean is essential for ensuring efficient engine operation after the overhaul.

Replacing Damaged Parts: Any components that are significantly worn out or damaged must be replaced with new ones. This could include pistons, bearings, piston rings, or the crankshaft if cracks or severe wear are found.

Component Reconditioning: Some parts, such as the cylinder head or engine block, can be reconditioned to fix minor damage. Reconditioning involves surface grinding and pressure testing.

Reassembly: Once all components have been repaired or replaced, the engine is carefully reassembled according to manufacturer specifications. This is a critical step to ensure all parts work harmoniously together.

Engine Testing: After reassembly, the engine is started and tested to ensure its performance is restored. Testing includes measuring pressure, temperature, and overall engine performance.

Common Field Incidents

During overhauls, various field incidents often arise. From my experience, here are some common occurrences:

Unexpected Oil Leaks: One of the most common problems after an overhaul is oil leaks. These can be caused by improperly installed seals or gaskets. In some cases, the engine may need to be disassembled again to fix the issue.

Overheating After Overhaul: I’ve encountered situations where the engine overheated after an overhaul, which was due to improper installation of cooling components. This highlights the importance of thorough inspection before reassembling the engine.

Lubrication System Failure: A faulty lubrication system can cause components to wear out quickly after an overhaul. This often happens when oil channels are clogged or the oil pump is defective.

Importance of Post-Overhaul Maintenance

After an engine overhaul, regular maintenance is key to keeping the engine in optimal condition. From my experience, many issues can be prevented with routine maintenance, such as regular oil changes, cooling system checks, and engine pressure monitoring. SSC Works also offers post-overhaul inspection and maintenance services to ensure your engine continues to perform at its best.