Bending: Definition, Function, and Its Application

“Bending” is a process of shaping materials by bending them at a certain angle. This process is widely used in various industries, including heavy machinery component manufacturing, metal fabrication, and custom component production. This article will explain the definition of bending, its applications in the heavy equipment industry, and how SSC Works uses this technique to produce high-quality components.

Definition of Bending

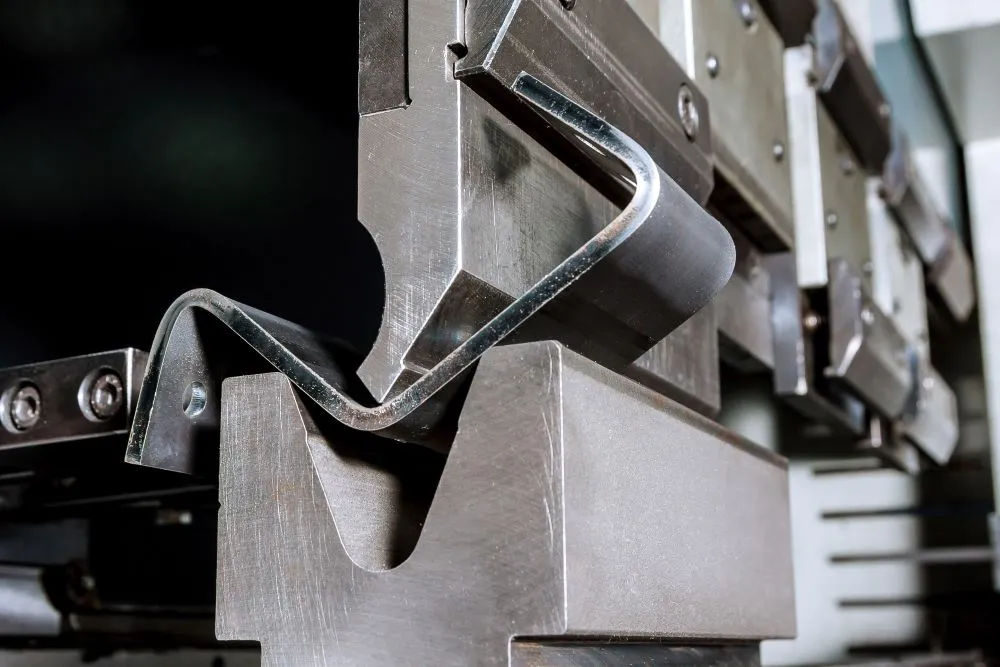

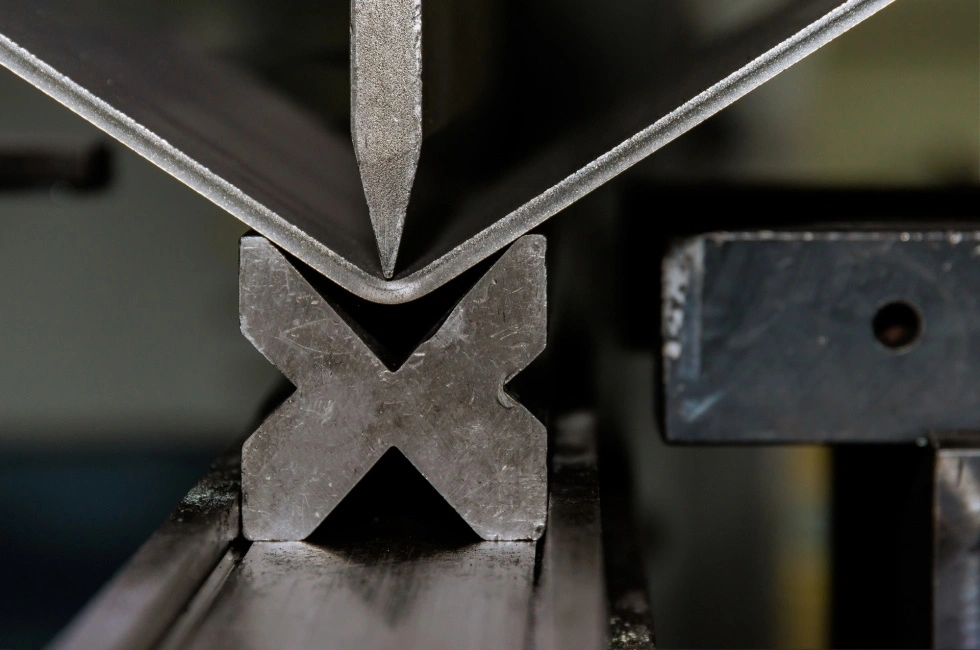

Bending is a plastic deformation process where a material, such as metal, is bent using pressure or force to form it into a specific angle or curve. This process is typically done using tools like bending machines or press brakes and can be applied to various materials, including steel, aluminum, and other metals.

Functions and Benefits of Bending

Bending serves many functions in the manufacturing industry, especially in the creation and modification of heavy equipment components. Some of the key functions and benefits of bending include:

Custom Component Creation: Bending allows the production of components with shapes and dimensions tailored to specific project needs, such as parts for mining vehicles or other industrial machinery.

Maintaining Material Strength: Bending allows materials to be shaped without cutting or welding, preserving their structural integrity.

Production Efficiency: The bending process can be carried out quickly and efficiently, allowing mass production of components at lower costs.

Design Flexibility: Bending provides flexibility in component design, especially for projects requiring specific shapes without damaging the original material.

Applications of Bending in the Heavy Equipment Industry

In the heavy equipment industry, bending is used to create various components for large machines such as excavators, dump trucks, and other mining equipment. Some examples of bending applications in this industry include:

Structural Component Manufacturing: Parts of the heavy machinery framework, such as beams, steel plates, or support structures, are often formed using the bending process.

Hydraulic System Components: Several parts of hydraulic systems used in heavy equipment are made using bending techniques, allowing the creation of pipes and tubes with the correct shape.

Custom Fabrication: Bending is frequently used for custom fabrication in special projects that require components with specific shapes and dimensions.

Common Incidents in the Bending Process

Several incidents can occur during the bending process, particularly when it is not executed correctly. Common problems include:

Cracking: If the material lacks sufficient strength or the bending angle is too sharp, cracks may develop in the material.

Wrinkling: In some materials, especially thinner metals, the bending process may cause wrinkles on the inside of the bend.

Dimensional Distortion: When pressure is uneven or too high, the material’s dimensions may deviate from the intended design.

Initial Handling for Bending Process Issues

To avoid these issues, initial handling is crucial. Some steps to take include:

Proper Machine Setup: Ensure the bending machine is set up correctly, especially regarding pressure and bending angles.

Selecting the Right Material: Use materials that are appropriate for the type and strength required to prevent cracking or wrinkling.

Regular Machine Maintenance: Regularly inspect and maintain bending machines to ensure optimal performance.

Bending at SSC Works: Guaranteed Quality for Your Project

At SSC Works, we use advanced technology and a team of experts in the bending process to ensure that every component produced meets the highest standards. Whether for individual projects or mass production, we have the capability to handle various types of bending work, from the simplest to the most complex.

SSC Works also serves a wide range of industries across Indonesia, including heavy equipment repair and custom component fabrication. With years of experience, we can provide the best solutions for your fabrication and heavy equipment repair needs.