Tools: Types, Functions, and Importance of Maintenance

Tools are devices used to assist humans in performing tasks, particularly in repair, maintenance, and manufacturing activities. In the heavy equipment industry, tools play a crucial role in ensuring the efficiency and reliability of equipment operations. This article will discuss the definition of tools, their types, functions, and the importance of tool maintenance, especially in the context of SSC Works as a provider of heavy equipment repair and maintenance services.

Definition and Function of Tools

Tools are devices designed to help people perform specific tasks, whether in daily activities, repairs, or construction. In the context of the heavy equipment industry, tools are used to repair or maintain various types of machinery, ensuring they continue to function properly.

The main function of tools is to simplify tasks that are difficult to do by hand. These tools can range from simple wrenches, hammers, and screwdrivers to more complex electronic devices such as machine scanners or calibration tools.

Types of Tools in the Heavy Equipment Industry

Some common types of tools used in the heavy equipment industry include:

Hand Tools: This category includes basic tools such as wrenches, pliers, hammers, and screwdrivers. These tools are used for daily repairs and maintenance on heavy machinery.

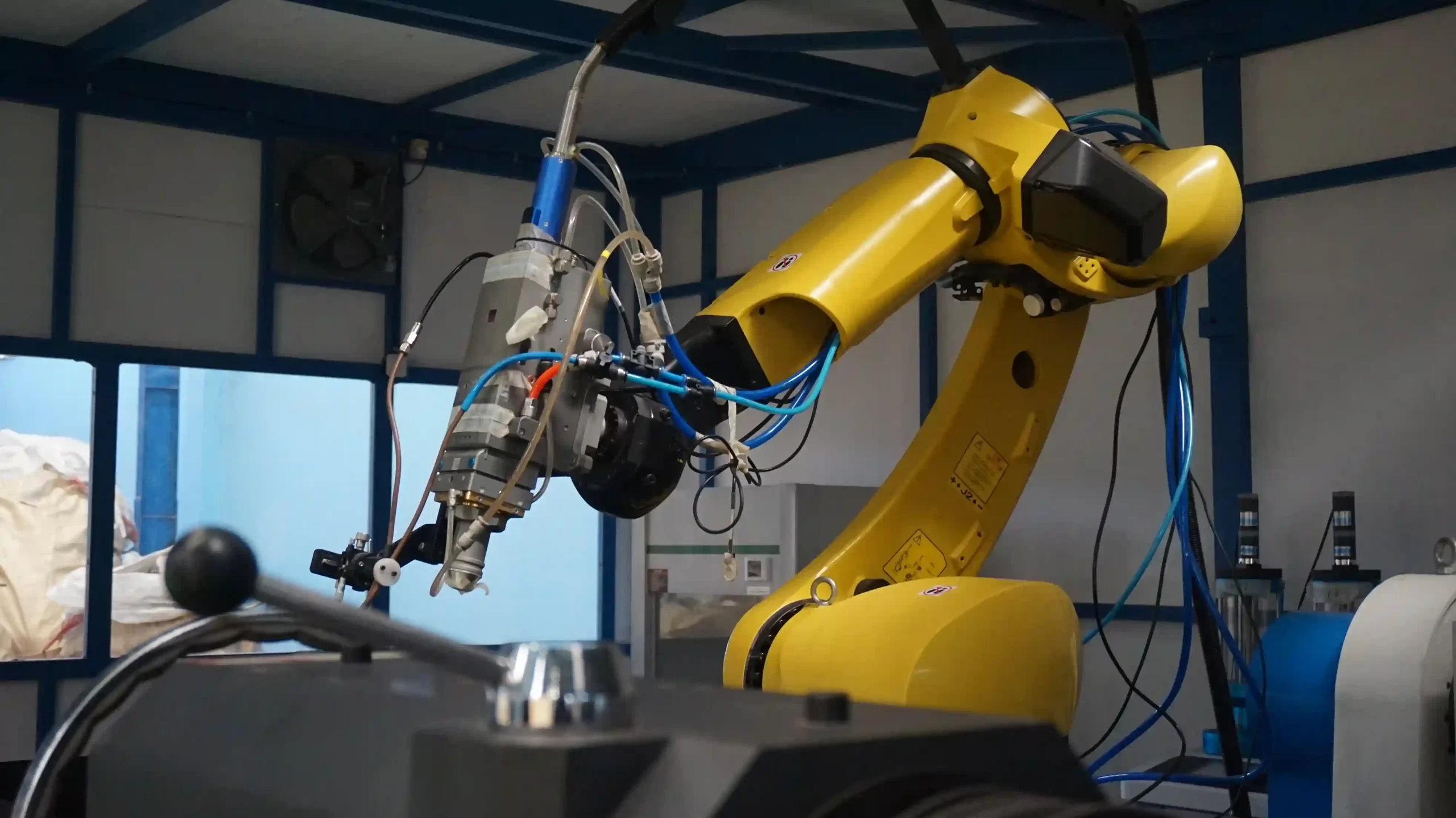

Power Tools: Electric tools like drills, saws, and grinders are essential for jobs requiring greater power and precision.

Hydraulic Tools: Hydraulic tools such as hydraulic jacks are used to easily lift and lower heavy components.

Diagnostic Tools: Diagnostic tools like machine scanners and pressure gauges are used to check the internal condition of machines, ensuring that components are functioning properly without having to disassemble the entire machine.

Importance of Tool Maintenance

Routine maintenance of tools is essential to maintaining their quality and lifespan. Here are several reasons why tool maintenance is important:

Preventing Tool Damage: Poorly maintained tools can wear out faster, which can ultimately damage other components on heavy machinery.

Improving Efficiency: Regularly maintained tools will work better and more efficiently, making the repair and maintenance process easier.

Cost Savings: Replacing damaged tools is far more expensive than performing routine maintenance. Proper tool maintenance also reduces the risk of downtime due to equipment failure.

Field Incidents Due to Poorly Maintained Tools

Neglecting tool maintenance can lead to several incidents that affect heavy equipment operations. Some common issues in the field include:

Hydraulic Failure: If hydraulic tools such as jacks are not well-maintained, the risk of lifting system failure increases, potentially causing serious damage.

Machine Damage: Worn-out tools such as wrenches or screwdrivers can damage bolts or other components on the machine, complicating the repair job.

Inaccurate Diagnostics: Poorly maintained diagnostic tools can provide incorrect results, potentially leading to misdiagnosis of heavy machinery issues.

SSC Works Solutions for Tool Repair and Maintenance

SSC Works not only provides heavy equipment repair services but also offers comprehensive solutions for the repair and maintenance of tools used in the heavy equipment industry. With extensive experience in handling various types of tools, SSC Works ensures that the tools used in the repair process are always in prime condition.

We also offer consultations regarding the selection and maintenance of tools, helping our clients get the best results from every tool they use. SSC Works is ready to be your partner in ensuring that the tools you use always work optimally to support the operation of your heavy equipment.