Fabrication of Chipsets Is Revolutionizing Heavy Equipment: Learn How!

Introduction

As technology advances, fabrication of chipsets is increasingly becoming crucial in heavy equipment. No longer confined to consumer electronics, chipsets are now integral to controlling systems and functions in heavy machinery such as excavators, bulldozers, and cranes, used in industries like mining and construction.

In this article, we will discuss what chipset fabrication is, its role in the technological revolution of heavy equipment, its benefits, and the challenges it presents. We will also explore common issues encountered in the field, particularly those related to chipset components, and the initial handling steps that can be taken to resolve these problems.

What Is a Chipset and How Does It Work in Heavy Equipment?

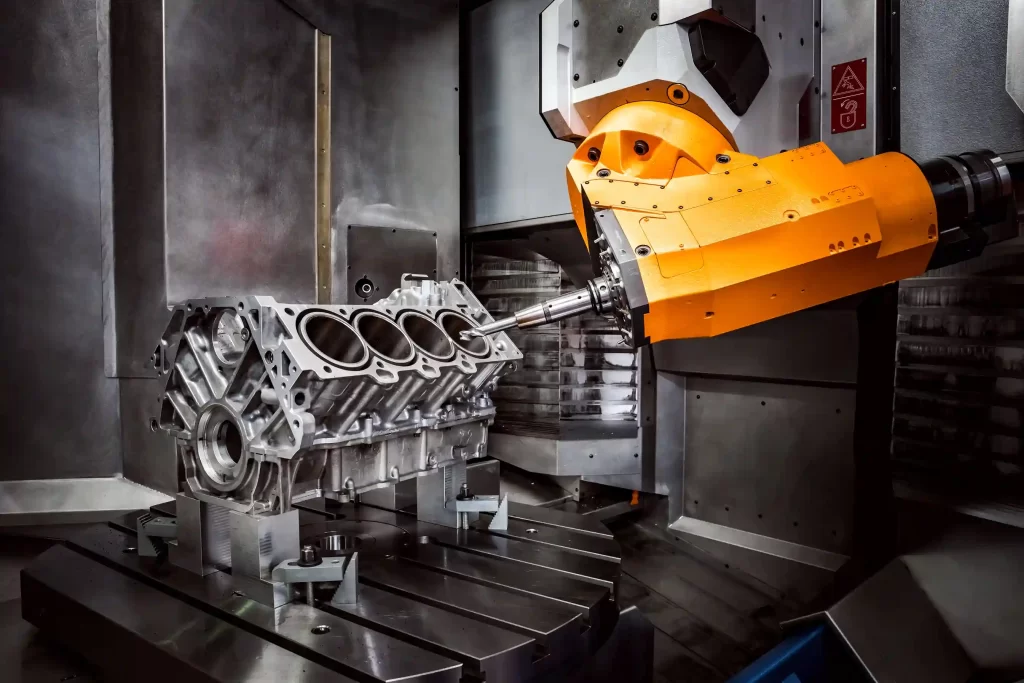

A chipset is a critical electronic component that serves as the control hub for various connected hardware devices. In the context of heavy machinery, chipsets regulate automated functions such as hydraulic control, braking systems, and fuel efficiency.

In the fabrication of heavy equipment, chipsets serve several key functions:

- Automation Control: Reduces human intervention by enabling automated operation, allowing machines to function more precisely.

- Energy Management: Chipsets help optimize fuel and energy use during heavy equipment operation.

- Machine Condition Monitoring: They enable early detection of wear or damage, providing automatic warnings before serious issues arise.

Heavy equipment relying on chipsets for fabrication includes:

- Smart Excavators: Using sensor technology regulated by chipsets for more accurate digging.

- Automated Dump Trucks: Utilizing chipsets for automatic control in hard-to-reach mining areas.

- Modern Bulldozers: Equipped with chipset-based electronic control systems that enhance efficiency and operator safety.

Benefits of Chipset Fabrication in Heavy Equipment

The fabrication of chipsets brings several significant benefits to the operation of heavy machinery:

- High Efficiency: Chipsets improve machine performance by reducing fuel consumption and minimizing downtime due to technical issues.

- Operational Accuracy: Chipsets help heavy equipment perform tasks with high precision, reducing operator errors.

- Safety: Chipset-based systems can detect potential hazards and activate safety features such as emergency shutdowns.

Chipset Technology Maintenance and Challenges

While chipset technology provides many advantages, maintaining it requires specific attention. Some tips for chipset care in heavy machinery include:

- Software Updates: Ensure chipsets and operating systems are regularly updated to maintain optimal performance.

- Connectivity Checks: Verify the connection between chipsets and sensors to prevent data communication issues.

- Cleaning and Cooling: Keep the chipsets in a clean, cool environment to prevent overheating and ensure proper function.

Common Chipset-Related Incidents in the Field

Several common incidents occur in the field related to chipsets in heavy equipment:

- Communication Failures: Chipsets lose connection with critical sensors, causing the machinery to lose its automation capabilities.

- Overheating: Chipsets overheat due to extreme work environments, leading to damage in control systems.

- Software Bugs or Malfunctions: When software isn’t updated or contains bugs, the chipsets may fail to perform their functions correctly.

Initial Handling of Chipset Issues

When chipset problems arise in the field, initial steps include:

- Shut down the equipment and allow the chipset to cool down if overheating occurs.

- Check sensor connectivity to ensure all hardware components are functioning properly.

- Restart the system or perform a hard reset in case of software malfunctions, and update if necessary.