What is Reconditioning? Benefits, Process, and Services

Reconditioning is the process of repairing, restoring, and bringing back damaged or underperforming equipment or components to their optimal working condition. This term is commonly used in the heavy equipment industry, where reconditioning may involve various procedures such as repairs, part replacements, and thorough inspections to ensure the equipment functions like new.

Reconditioning is a highly sought-after solution, especially for companies looking to extend the life of their equipment without the high cost of purchasing brand-new units.

Why is Reconditioning Important?

Reconditioning heavy equipment offers significant benefits, especially in terms of efficiency and cost savings:

- Cost-Effective: Purchasing new heavy equipment can be extremely expensive. Reconditioning provides a more affordable option, where you only pay for the necessary repairs or part replacements.

- Extends Equipment Lifespan: Reconditioning allows older or damaged equipment to function optimally again, extending its usage for many more years.

- Reduces Downtime: Reconditioning is done quickly and efficiently, allowing the equipment to be back in use much faster than waiting for a new one.

- Improves Performance: The reconditioning process often enhances various components, improving the overall performance of the heavy equipment, bringing it closer to its original condition.

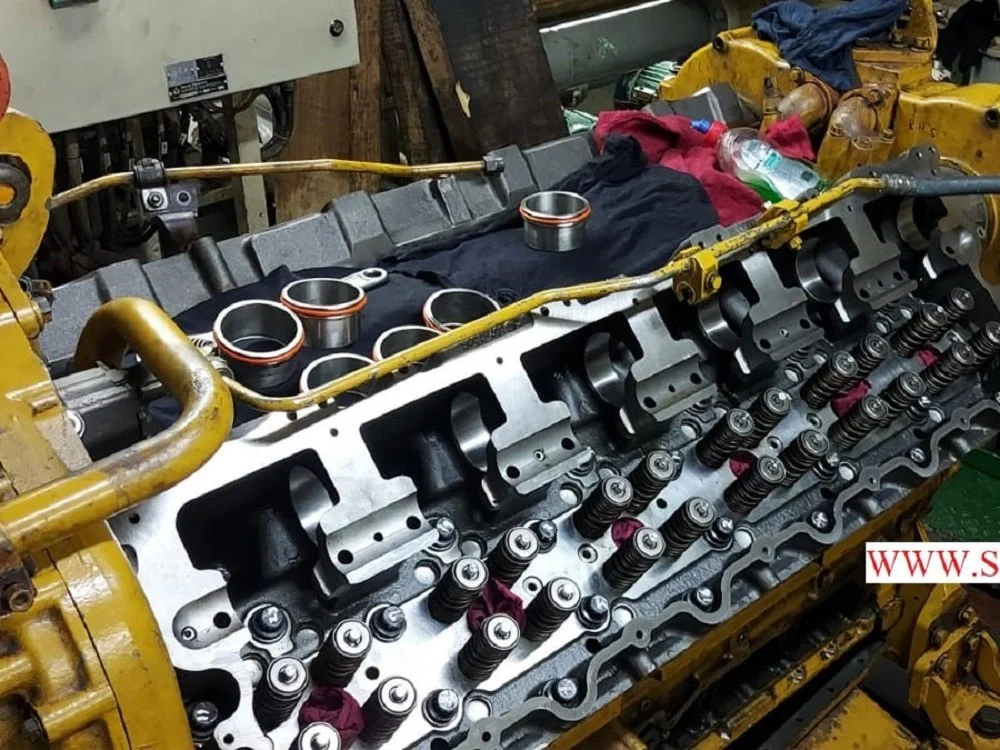

Heavy Equipment Reconditioning Process

The reconditioning process for heavy equipment involves several stages, including:

- Inspection and Diagnosis: Expert technicians conduct thorough inspections to identify any damage or components that need repair.

- Repair and Replacement: Damaged components are repaired or replaced with new or refurbished parts that are in good condition.

- Performance Testing: After repairs, the equipment undergoes testing to ensure all functions are running optimally and no issues remain.

- Finishing and Repainting: Heavy equipment is often given a new finish or repainted to enhance its appearance, giving it a like-new look.

Frequently Reconditioned Components

Some heavy equipment components that are frequently reconditioned include:

- Engines: Engines are often the main focus of reconditioning as they are the heart of any heavy equipment.

- Hydraulic Systems: Hydraulic systems are commonly reconditioned, especially when there are leaks or performance degradation.

- Transmissions and Gearboxes: Damage to transmissions can severely impact the overall performance of heavy equipment, making reconditioning essential.

- Undercarriage: The undercarriage, such as tracks or wheels, is often reconditioned due to wear from heavy usage.

When Should Reconditioning Be Done?

Reconditioning is needed when equipment starts showing signs of performance decline or significant damage. Some common indications that your heavy equipment needs reconditioning include:

- Loss of power or performance.

- Strange noises or vibrations during operation.

- Damage to critical components like the engine or hydraulic system.

- The equipment is aging without undergoing major maintenance.

Why Choose SSC Works for Reconditioning?

SSC Works specializes in heavy equipment reconditioning and repair. With a team of experienced technicians and advanced tools, we ensure that every piece of equipment reconditioned by us functions like new. Our services are designed to provide cost-effective, fast, and reliable reconditioning solutions.

If your heavy equipment needs reconditioning, don’t hesitate to contact SSC Works. We offer comprehensive reconditioning services to ensure your heavy equipment remains in peak condition. Reach out to us now for the best reconditioning solutions that will save you money and improve your equipment’s performance!