Intermittent Meaning: Understanding Its Definition and Application in Industry

What Is “Intermittent”?

The word intermittent refers to something that occurs at irregular intervals or pauses temporarily. In industrial and technological contexts, this term is often used to describe a process or condition that happens periodically or with certain breaks.

Usage of “Intermittent” in Industry

In various industries, including manufacturing, heavy equipment repair, and the energy sector, intermittent often refers to processes or operations that do not run continuously but rather in cycles or intervals.

Examples:

Machine Operation: Some machines in factories may operate in intermittent mode, meaning they only run when necessary or under specific conditions. This is commonly applied to energy-intensive machines for efficiency purposes.

Heavy Equipment Maintenance: In the heavy equipment industry, intermittent maintenance refers to periodic maintenance performed depending on the condition or operational time of the equipment.

The Importance of Understanding Intermittent Conditions in Heavy Equipment Repair

In heavy equipment, understanding whether a component operates in intermittent mode is crucial for planning maintenance and repairs. Here are some examples related to this term:

Intermittent Machine Issues: Conditions where the machine occasionally stops or malfunctions can indicate damage to components like fuel systems, electrical systems, or sensors. In such cases, intermittent repair is needed before the problem worsens.

Intermittent Hydraulic System Maintenance: Hydraulic systems in excavators or other heavy equipment often experience problems that appear intermittently. Performing intermittent maintenance, such as replacing filters or checking hydraulic pressure, can help extend equipment life.

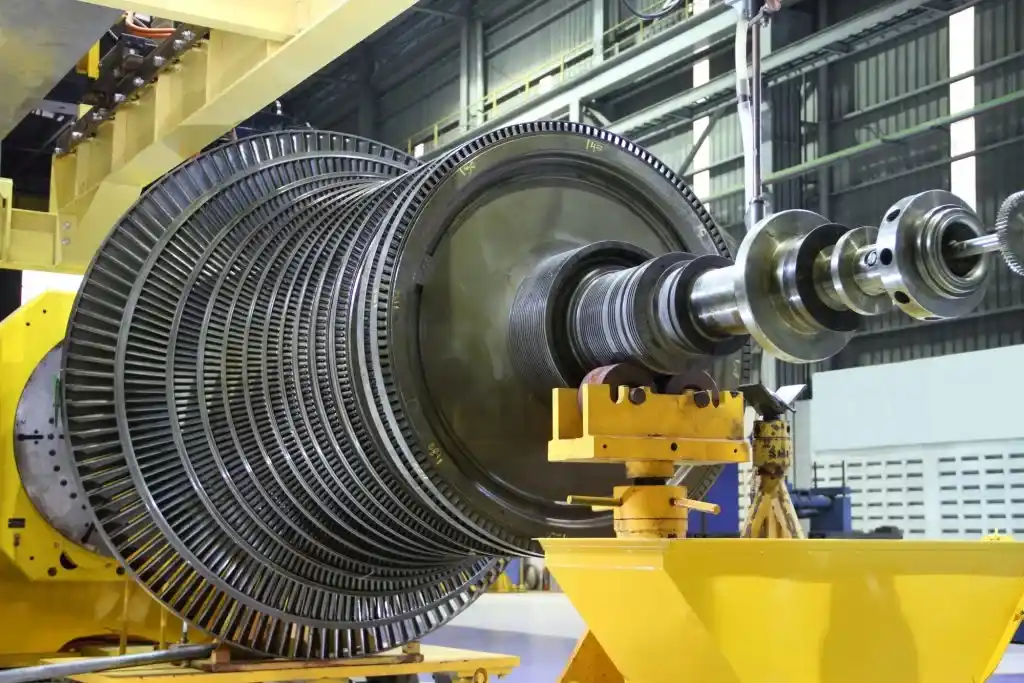

Repair of Large Components: Many major repairs, such as re-chrome hydraulic systems or rebuilding engine blocks, are performed intermittently, depending on needs and operational schedules.

Intermittent and Operational Efficiency

Running a system or machine in intermittent mode can often improve operational efficiency. Some benefits include:

Energy Savings: Continuously running a machine consumes more energy. Intermittent operation allows energy use only when needed.

Reducing Wear and Tear: Using machines periodically allows components to rest, reducing overheating and extending the life of the machine.

Better Planning: By knowing when and how often a component or machine operates in intermittent mode, companies can plan better maintenance schedules and avoid unexpected downtime.

Examples of Intermittent Applications in Heavy Equipment

Here are examples of heavy equipment that often operates in intermittent mode:

- Cranes: Cranes are used periodically depending on the needs of a construction or lifting project.

- Mining Excavators: Excavators are often operated intermittently based on the requirements of digging and material transportation.

- Industrial Generators: Backup generators typically operate intermittently only during power outages.

Conclusion: Intermittent and SSC Works

Understanding the meaning of intermittent and how this condition affects heavy equipment operation is crucial for maintaining productivity and efficiency. SSC Works is ready to help you address intermittent repair issues with scheduled maintenance services. We provide solutions to ensure that your heavy equipment runs smoothly, even in intermittent operational conditions.

If you’re dealing with intermittent operational issues with your heavy equipment, feel free to contact SSC Works. Our team is ready to assist you with the best repair and maintenance solutions to ensure your machinery keeps running smoothly.