What Is a Track Frame? Function, Usage, and Maintenance in Heavy Equipment

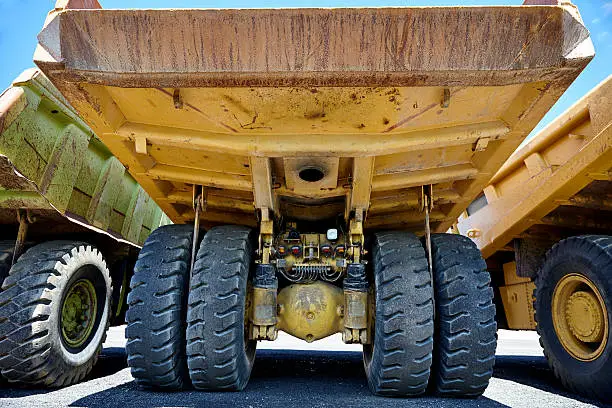

A track frame is a critical component in heavy machinery, especially for vehicles that use a track or chain system, such as bulldozers and excavators. The track frame acts as the support structure and path for the movement of the tracks, allowing these heavy vehicles to move steadily on rough terrains like muddy, rocky, or steep surfaces.

Primary Functions of the Track Frame

The track frame plays a crucial role in maintaining the stability and movement of heavy equipment. Its primary functions include:

Supporting Vehicle Weight

The track frame is designed to bear the heavy load of the vehicle, evenly distributing the pressure across the tracks to ensure smooth movement.Enabling Movement on Difficult Terrain

Heavy machinery is often operated on tough terrains, such as wet or rocky ground. The track frame helps maintain the vehicle’s stability and traction on these challenging surfaces.Protecting Internal Components

The track frame also protects vital internal components like track rollers, sprockets, and idlers from damage caused by external impacts or harsh elements.

Uses of Track Frame in Heavy Industry

Track frames are essential in several industries, especially those related to construction, mining, and forestry. Some key applications include:

- Construction: In large construction projects, track frames allow heavy machinery like bulldozers and excavators to move safely across various terrains.

- Mining: In the mining industry, track frames are essential for machines that operate in muddy or rocky environments, ensuring that vehicles can continue to function smoothly.

- Forestry: Track frames enable heavy machinery to traverse uneven forest terrain

Track Frame Maintenance

To keep the track frame performing optimally and lasting longer, routine maintenance is necessary. Some maintenance steps include:

Regular Cleaning: Cleaning the track frame of dirt, mud, and rocks is crucial to prevent damage to other components.

Visual Inspections: Regularly inspect for cracks or damage on the track frame. Early detection can prevent larger, more costly repairs.

Component Lubrication: Ensure that all moving parts on the track frame are properly lubricated to reduce friction and prevent early wear and tear.

Causes of Track Frame Damage

Track frames can experience damage due to several factors, including:

- Excessive Use: Long operational hours or working in extremely tough conditions without breaks can lead to excessive wear on the track frame.

- Extreme Terrain Conditions: Extremely rocky or muddy terrains can accelerate wear and tear.

- Lack of Maintenance: Failing to regularly clean or lubricate the track frame can lead to faster deterioration.

Conclusion: Why Track Frames Are Crucial

The track frame is one of the most vital components of heavy machinery, directly affecting vehicle performance in the field. Proper maintenance can extend the life of heavy equipment and prevent costly downtime.

If you’re facing issues with your track frame or any other component on your heavy machinery, don’t hesitate to contact SSC Works. We provide repair and refurbishment services to ensure your heavy equipment continues to operate optimally under all conditions.