Challenges in Casting and SSC Works’ Solutions

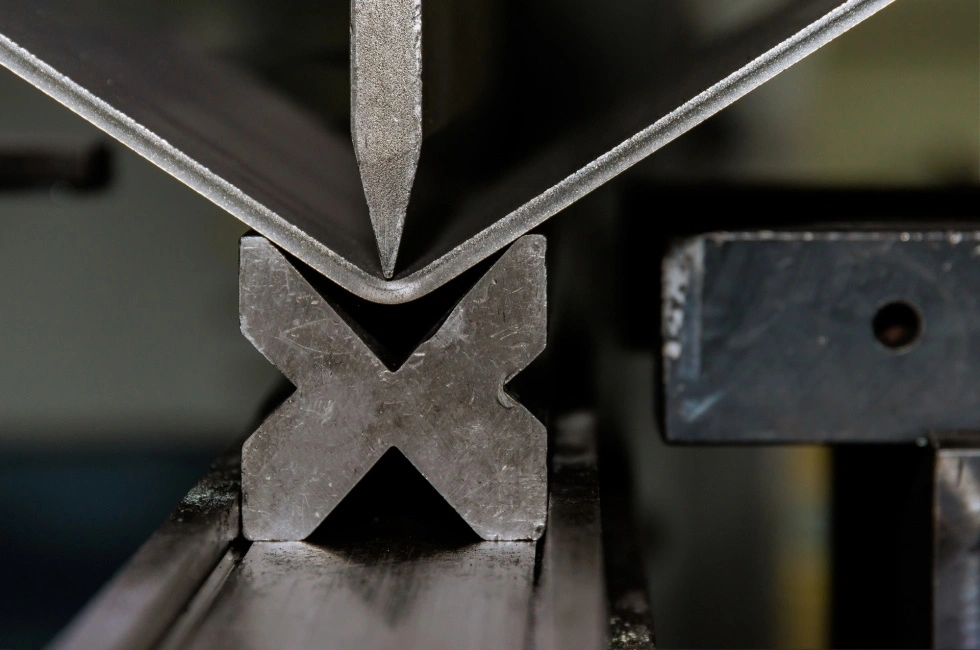

While casting is a versatile technique, challenges such as casting defects and tight tolerances can arise. SSC Works addresses these challenges through:

Strict Temperature Control

Ensuring the correct temperature of molten material is crucial to prevent defects. At SSC Works, we use advanced technology to accurately monitor and control temperatures.High-Quality Molds

The precision of mold-making is key to producing high-quality components. We use premium mold materials and modern equipment to cast components with accuracy.Rigorous Quality Testing

All components produced through casting undergo strict testing to ensure strength, durability, and adherence to the required specifications.

Conclusion

The casting process is an ideal solution for manufacturing components from raw materials with complex shapes and sizes. At SSC Works, we offer custom casting services tailored to meet the needs of various industries. With our expertise in casting, we can produce heavy equipment parts and other industrial components of the highest quality.

If you need casting services for custom components, contact us today to discuss your needs. We are ready to provide the right casting solution for your project.