Chamfering in Industry: Functions, Benefits

What is Chamfering and Why is it Important in Industry?

Chamfering is the process of smoothing or trimming sharp edges on the edges of metal components or other materials, creating a sloped edge called a chamfer. This process is widely applied across industries, including automotive, manufacturing, construction, and mining. Chamfering ensures that the produced components have safe, precise edges, making them easier to assemble with other parts and reducing the risk of damage during assembly or operation.

As one of the services provided by SSC Works, chamfering offers more than aesthetic appeal; it contributes to the longevity of components and user safety. This article delves into the functions, benefits, methods, and how SSC Works provides high-quality chamfering services to meet your needs.

The Functions of Chamfering in Industrial Processes

Chamfering plays an essential role across industrial sectors, enhancing safety and extending component lifespan. Here are some primary functions of chamfering in industrial processes:

1. Removing Potentially Hazardous Sharp Edges

Components with sharp edges can pose injury risks for workers and may damage other components during assembly. Chamfering smoothens these edges, making them safer to handle and install.

2. Easing the Assembly Process

Chamfered edges allow components to be assembled more easily and precisely, especially in industries that require exact alignment. Chamfered angles help in precise component alignment without damaging adjacent parts.

3. Enhancing Aesthetics and Finishing

In addition to functionality, chamfering provides a more aesthetically pleasing finish, giving components a professional, polished look, especially in industries that emphasize visual details.

4. Improving Strength and Durability of Components

Chamfering reduces stress on component edges, enhancing durability and lowering the risk of cracks or damage on these parts.

Benefits of Chamfering in Construction and Mining Industries

1. Reducing Material Damage

Materials processed through chamfering are more resistant to impact or wear during operations. This is crucial in heavy industries such as mining and construction that use large and thick metal components.

2. Lowering Maintenance Costs

Chamfered components have a longer lifespan and require less maintenance. By reducing edge stress, the likelihood of component damage decreases, allowing companies to save on maintenance costs.

3. Boosting Work Efficiency

Chamfered components are easier to install and more stable within machinery systems, resulting in shorter installation times and increased production efficiency. This is a significant advantage, especially in construction and mining projects that demand speed and efficiency.

Common Chamfering Methods Used in Industry

In the industry, several chamfering methods are tailored to different materials and specific needs. Here are the most commonly used chamfering methods:

1. Manual Chamfering

Manual chamfering is done with handheld tools, ideal for small and intricate parts. This method is often used in prototyping or on components that require high precision.

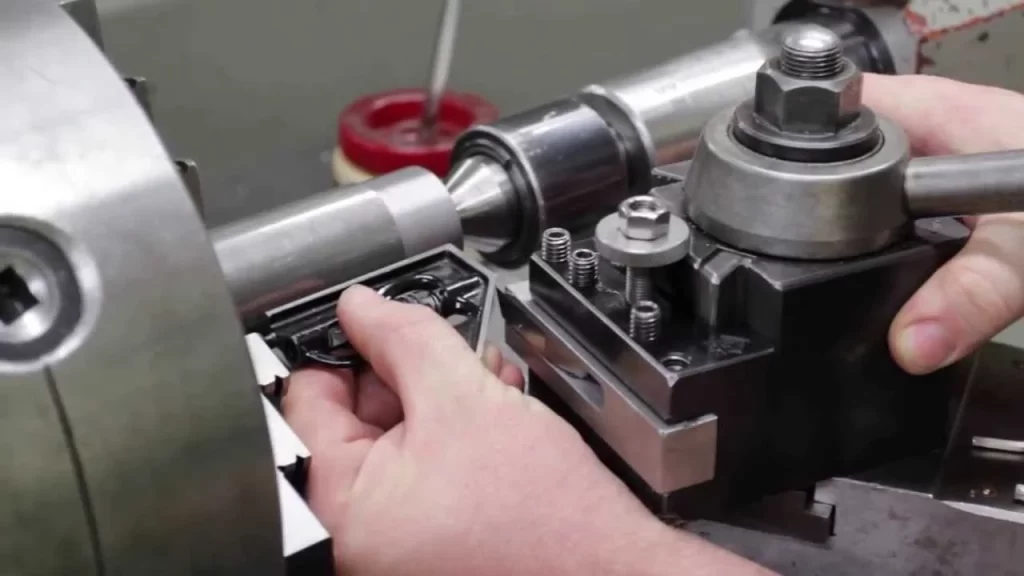

2. CNC Chamfering

CNC machines are used to produce precise chamfers on large, dense metal parts. This method is suitable for mass production and provides consistent results.

3. Grinding Machine Chamfering

Grinding machines are used for chamfering on larger, heavier components such as pipes or metal plates. These machines quickly smoothen edges, making them ideal for high-volume component production.

4. Chemical Chamfering

In some cases, chamfering is done chemically, particularly on very brittle or challenging-to-chamfer materials using mechanical methods.

Precision Chamfering Process for Quality and Durability

To ensure optimal chamfer quality, SSC Works follows several critical steps in the chamfering process:

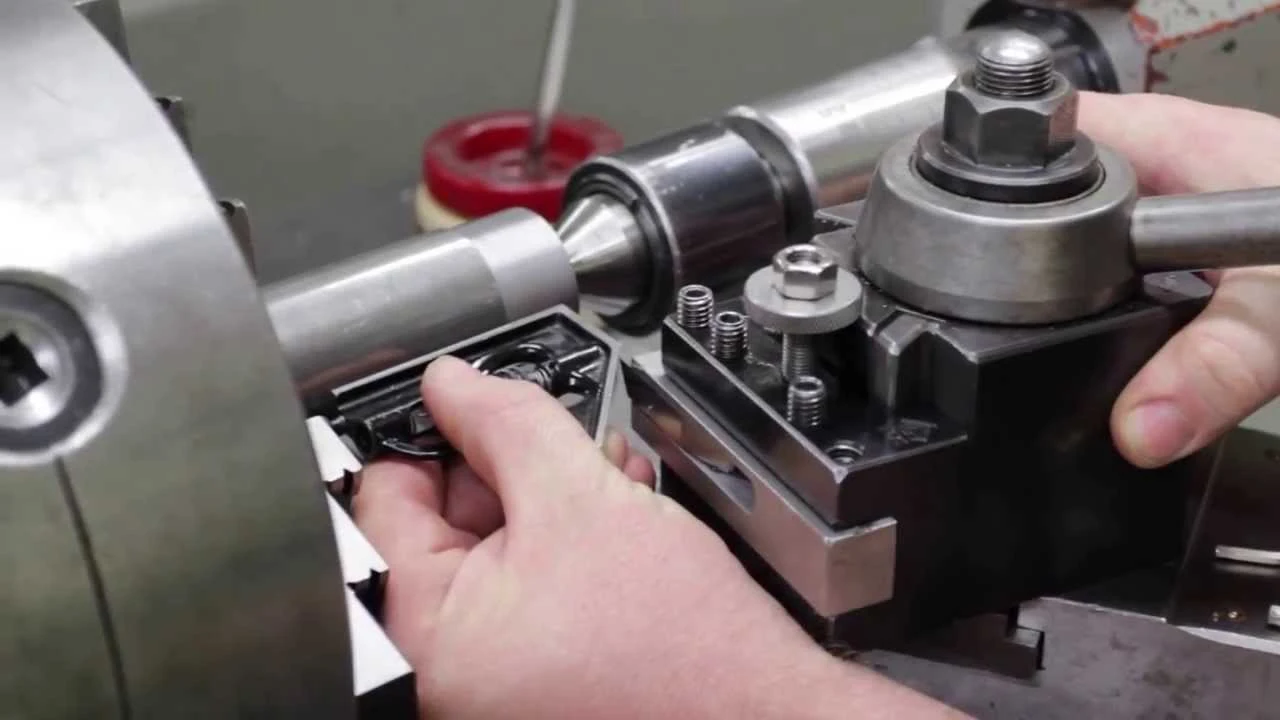

1. Selecting the Right Tools

Choosing the right tools for the material type and component thickness is essential in chamfering. SSC Works uses high-quality tools to ensure precise and smooth chamfer results.

2. Accurate Angle Setting

Setting the correct chamfer angle is vital to ensure the component has the desired shape without damaging the material. The SSC Works team is skilled in determining the ideal chamfer angle for various industrial applications.

3. Quality Control

After the chamfering process, each component undergoes strict inspection to ensure the chamfer meets quality and safety standards. This quality control ensures that components are ready for use without any risk of failure.

SSC Works: Chamfering Solutions for Your Industrial Needs

As a provider of heavy equipment repair and maintenance services, SSC Works not only supplies quality components but also offers professional chamfering services to ensure each component operates optimally. Here are the advantages of SSC Works’ chamfering services:

1. Customizable Chamfering Services

We offer chamfering services tailored to your specific needs, for both standard and custom components. SSC Works understands that each industry has unique requirements.

2. Highly Skilled Expert Team

Our team consists of professionals skilled in chamfering techniques for various components and materials. With their expertise and experience, SSC Works can deliver results that meet industrial standards.

3. After-Sales Support and Maintenance

Beyond chamfering, SSC Works provides full support through after-sales and maintenance services. This makes us a reliable partner for all your needs, from repair to component maintenance.

4. Original and Custom Component Options

We provide options for original (OEM) and custom components with chamfers designed to specification. Whatever your needs, SSC Works is ready to meet your heavy equipment chamfering requirements with durable results.

Chamfering for Durability and Efficiency

Chamfering is a crucial part of the industry that enhances component safety, durability, and aesthetics. With its many benefits, chamfering is an essential solution across sectors, especially for heavy equipment and machines with large metal components.

Trust your chamfering needs to SSC Works! We are ready to support your heavy equipment performance through high-quality chamfering services, whether for original or custom components. Contact us today to learn more about the chamfering solutions we offer, and make SSC Works your trusted partner for your industry needs.