Understanding Dipper s and Their Role

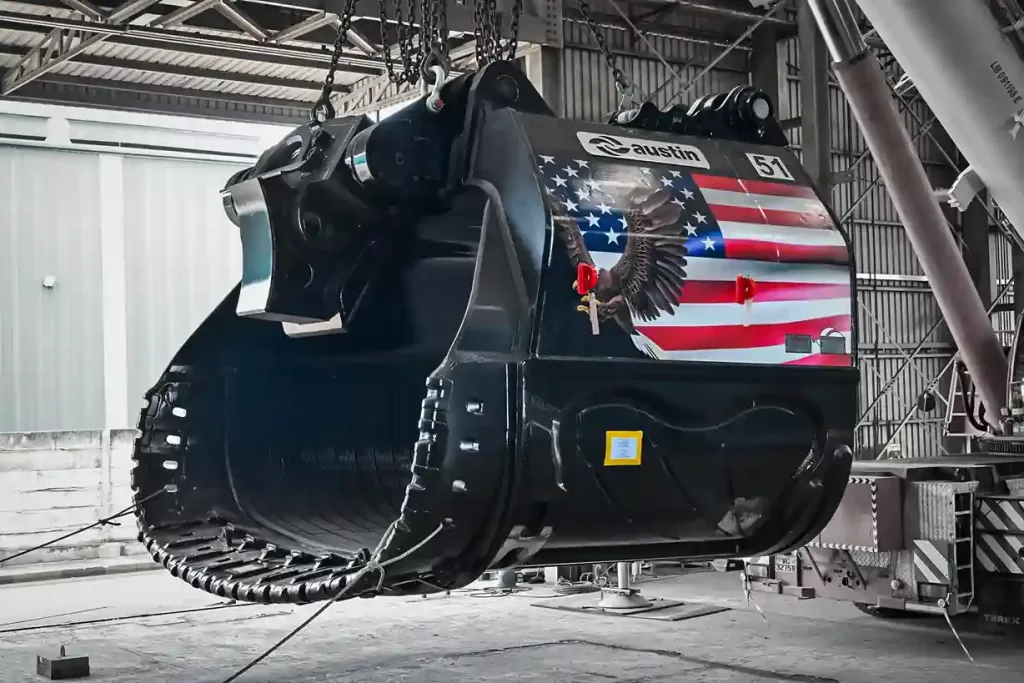

A dipper is a large, bucket-like attachment that serves as an essential component of heavy machinery such as excavators and shovels. It is designed to dig, lift, and transport materials like soil, rocks, and minerals. In industrial operations, dippers play a strategic role, especially in:

Mining: Extracting materials from open-pit and underground mines.

Construction Projects: Transporting large volumes of materials efficiently.

Infrastructure Development: Supporting large-scale excavation tasks.

Primary Functions of a Dipper

Material Handling: Efficiently lifting and transporting heavy loads.

Excavation: Penetrating dense materials such as clay and rocks.

Material Loading: Filling haul trucks or conveyor belts for further processing.

Types of Dippers

Standard Dippers: Suitable for general digging tasks.

Rock Dippers: Reinforced for handling abrasive and heavy materials.

High-Capacity Dippers: Ideal for large-scale mining operations with massive material volumes.

Common Issues with Dippers and Solutions

While designed for heavy-duty tasks, dippers are not immune to issues. Here are common problems and their solutions:

Material Wear and Tear: Caused by continuous friction with heavy materials.

Solution: Use wear-resistant materials like high-strength steel and schedule regular part replacements.

Cracks in Welds: Resulting from heavy stress.

Solution: Conduct regular visual inspections to detect early cracks.

Hydraulic System Failures: Affecting the movement of the dipper.

Solution: Perform routine checks on hydraulic systems and replace faulty components promptly.

Overloading: Exceeding the recommended capacity accelerates wear and damage.

Solution: Train operators to adhere to equipment specifications.

Technological Innovations in Dippers

Technological advancements have introduced various innovations to enhance the efficiency and lifespan of dippers:

Modern Wear-Resistant Materials: Minimizing wear and extending usage life.

Lightweight but Durable Designs: Reducing operational load.

Smart Monitoring Systems: Using sensors to detect wear or damage early.

Protective Coatings: Applying special coatings to prevent corrosion in extreme environments.

Preventive Measures and Common On-Site Incidents

Field operations often encounter unexpected incidents involving dippers. Some examples include:

Dipper Detachment from the Machine Arm: Caused by locking system failure.

Initial Action: Halt operations immediately, inspect safety locks, and replace them if necessary.

Material Stuck in the Dipper: Hindering operational efficiency.

Initial Action: Use auxiliary tools to safely dislodge the material.

Internal Component Breakage: Due to overuse beyond capacity.

Initial Action: Replace damaged components and recalibrate operational settings.

SSC Works: Your Trusted Dipper Maintenance Partner

SSC Works provides reliable solutions for all your dipper needs. Our services include:

Custom Fabrication: Crafting dippers tailored to your specific operational requirements.

Comprehensive Repairs: Restoring optimal performance of your heavy equipment.

Preventive Maintenance: Ensuring your machinery remains in peak condition and minimizing downtime.

With our expertise, your dipper will always be ready to tackle field challenges.

Conclusion

Dippers are a vital component in enhancing efficiency in mining and construction industries. With proper understanding, technological innovations, and regular maintenance, their performance can be optimized. Trust SSC Works for your dipper maintenance needs and experience unparalleled service excellence.