Deburring: Precision and Safety

Deburring

Deburring is a vital process in heavy equipment manufacturing and maintenance. This technique involves removing sharp edges, burrs, or imperfections left after machining, ensuring the components are safe, functional, and precise. At SSC Works, we specialize in professional deburring services to enhance the reliability and performance of your equipment.

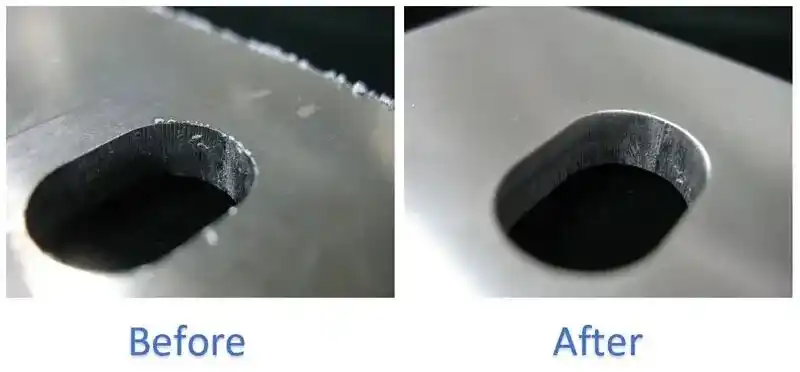

What Is Deburring?

Deburring is the process of smoothing and polishing the rough edges or irregularities that form during machining, welding, or fabrication. These imperfections can cause significant issues, such as:

- Operational inefficiency: Misaligned or uneven parts reduce machine accuracy.

- Safety hazards: Sharp burrs can lead to injuries for operators.

- Component wear: Burrs can increase friction, leading to faster degradation

Why Is Deburring Important?

Improves Equipment Performance

- A smooth surface reduces friction between components, enhancing efficiency and longevity.

Ensures Operator Safety

- By eliminating sharp edges, deburring minimizes the risk of accidents.

Enhances Aesthetic Appeal

- Properly deburred components not only perform better but also look professional and well-finished.

Facilitates Assembly

- Smooth edges ensure seamless fitting and alignment of parts, preventing assembly delays.

Techniques Used in Deburring

At SSC Works, we employ advanced deburring techniques tailored to your needs:

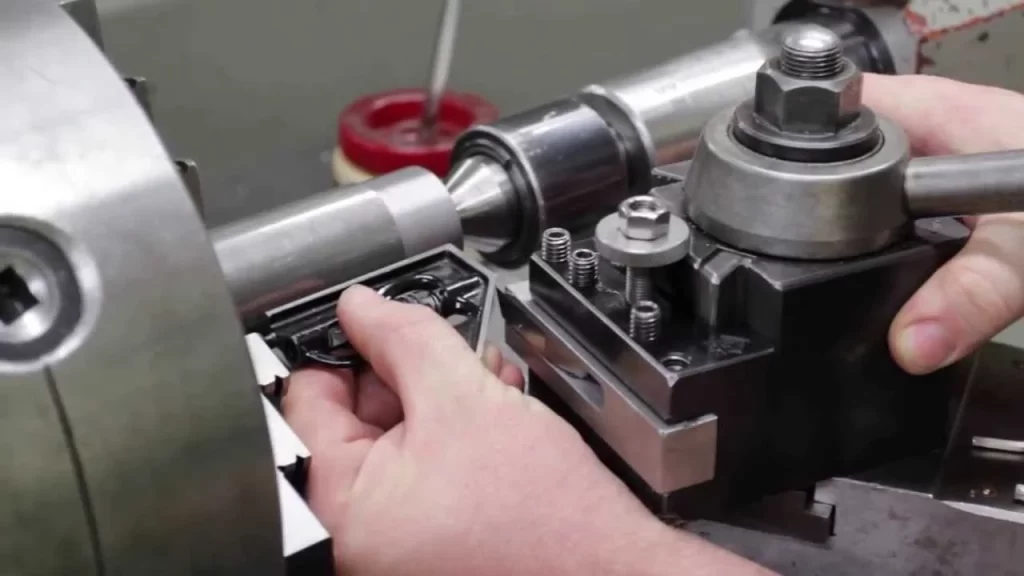

Manual Deburring

- Skilled technicians use hand tools to remove burrs in intricate or small areas.

Mechanical Deburring

- Machines like grinders, tumblers, and brushes handle larger or repetitive tasks efficiently.

Thermal Deburring

- This method uses heat to remove burrs from hard-to-reach areas.

Electrochemical Deburring

- Ideal for precision components, this process involves using an electrolyte solution and electrical current to dissolve burrs.

Applications of Deburring in Heavy Equipment

- Hydraulic Systems: Removing burrs ensures smooth fluid flow and prevents leaks.

- Gear Mechanisms: Burr-free gears enhance precision and reduce wear.

- Structural Components: Deburring eliminates weak points that may compromise strength.

- Custom Fabrications: Ensures your custom parts meet exact specifications.

Common Issues Without Deburring

- Premature wear and tear of components.

- Increased downtime due to breakdowns or improper fits.

- Injuries caused by handling sharp-edged parts.

Why Choose SSC Works for Deburring?

Expertise:

- Our team has years of experience in precision deburring for heavy equipment.

Advanced Technology:

- We use cutting-edge tools and methods to achieve optimal results.

Custom Solutions:

- We tailor our deburring services to suit your specific components and requirements.

End-to-End Support:

- From inspection to finishing, we ensure every part meets the highest quality standards.

Contact SSC Works for Reliable Deburring Services

Trust SSC Works to improve the safety, efficiency, and durability of your heavy equipment components through professional deburring.

📞 Click here to contact us via WhatsApp and let us provide you with the best solutions for your machining needs!