Automated Mechanical Systems: Enhancing Efficiency and Productivity

In today’s fast-paced industrial landscape, automation plays a pivotal role in increasing efficiency and reducing human error. Automated mechanical systems, in particular, are revolutionizing various sectors, including manufacturing, mining, and heavy machinery operations. This article will provide an in-depth exploration of automated mechanical systems, their applications, and how SSC Works can assist with maintenance solutions for these advanced systems in mining equipment.

1. What Are Automated Mechanical Systems?

Automated mechanical systems are machines or equipment that perform tasks without the need for direct human intervention. These systems are typically controlled by advanced software, sensors, and actuators, allowing them to carry out complex operations accurately and efficiently.

Automation ranges from simple mechanical processes, such as assembly lines, to more complex systems involving robotics and artificial intelligence. Automated mechanical systems are widely used across various industries, including manufacturing, transportation, mining, and healthcare, to improve productivity, precision, and safety.

2. Applications of Automated Mechanical Systems

Automated mechanical systems are utilized in numerous industries, each requiring specialized solutions to enhance operations. Let’s dive into some of the key applications of these systems:

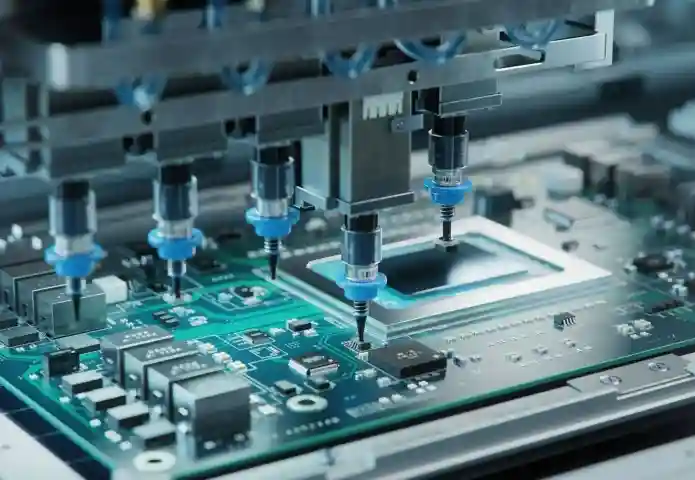

a. Manufacturing and Assembly Lines

One of the earliest and most significant applications of automated mechanical systems is in manufacturing, particularly on assembly lines. Automated machinery can perform repetitive tasks such as welding, painting, and assembling components much faster than manual labor, while maintaining consistent quality.

Benefits:

- Increased production speed.

- Minimized human error.

- Cost-effective in the long term.

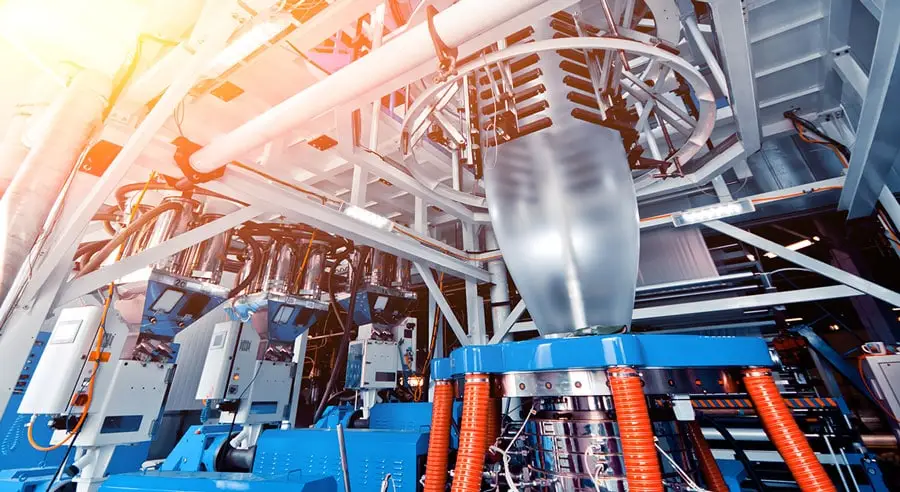

b. Mining Operations

Automation has become a key factor in improving productivity and safety in the mining sector. Automated mechanical systems in mining include automated drilling machines, conveyor belts, and ore transport trucks.

Benefits:

- Improved precision in drilling and excavation.

- Reduced human exposure to hazardous environments.

- Enhanced efficiency in material handling.

c. Agriculture

Automated mechanical systems have also entered the agricultural industry, with automated harvesters, tractors, and irrigation systems becoming increasingly common. These machines optimize farming practices and reduce labor demands.

Benefits:

- Increased crop yield.

- Reduced labor costs.

- More efficient use of resources, such as water and fertilizer.

d. Automotive Industry

The automotive industry is another area where automated mechanical systems thrive. Robots are used for welding, painting, and assembling car parts, which significantly speeds up production.

Benefits:

- Faster production timelines.

- Improved safety in manufacturing.

- Enhanced accuracy in assembly.

3. Benefits of Automated Mechanical Systems

Automated mechanical systems provide numerous benefits across industries. Let’s explore how these systems can positively impact operations:

a. Increased Productivity

One of the primary advantages of automation is the substantial increase in productivity. Automated systems can operate 24/7 without fatigue, leading to higher output levels than human workers. Additionally, these systems work faster and more consistently, ensuring high productivity in various industries.

b. Improved Safety

In hazardous environments such as mining and construction, automated systems can perform dangerous tasks, thereby reducing the risk to human workers. For instance, automated drilling machines can operate in extreme temperatures or unstable conditions, ensuring worker safety.

c. Precision and Consistency

Automated systems excel in tasks that require precision and accuracy. In manufacturing, they ensure consistent production quality, while in agriculture, they apply fertilizers or pesticides in measured quantities, reducing waste.

d. Cost Efficiency

Although the initial investment in automated mechanical systems can be high, the long-term cost savings are substantial. Automation reduces labor costs, increases production efficiency, and minimizes errors, which can lead to significant financial benefits over time.

4. Future Trends in Automated Mechanical Systems

The future of automated mechanical systems is exciting, with rapid advancements in technology set to bring even greater capabilities. Some key trends to watch for include:

a. Integration of Artificial Intelligence (AI)

Artificial intelligence will continue to enhance automated systems, allowing machines to learn from data and improve their performance over time. In industries like manufacturing and mining, AI-powered automation can optimize processes, predict maintenance needs, and even adapt to changing conditions autonomously.

b. Collaborative Robots (Cobots)

Collaborative robots, or cobots, are designed to work alongside human operators in industrial settings. Unlike traditional robots, cobots are equipped with sensors to detect human presence, ensuring safe and efficient collaboration.

c. Autonomous Vehicles

In the mining industry, autonomous vehicles such as trucks and loaders are gaining popularity. These vehicles can transport heavy loads without human intervention, reducing labor costs and improving safety in harsh environments.

d. IoT-Enabled Automation

The Internet of Things (IoT) is expected to play a significant role in automating mechanical systems. IoT devices can collect data from machines, monitor performance, and enable predictive maintenance, ensuring optimal functionality of automated systems.

5. Challenges of Implementing Automated Mechanical Systems

While the benefits of automated mechanical systems are substantial, there are also challenges that organizations must address:

- High Initial Costs: The cost of purchasing and installing automated systems can be a significant barrier for some companies. However, these costs are typically offset by long-term savings in labor and increased productivity.

- Skilled Labor Shortage: Implementing and maintaining automated systems requires skilled technicians and engineers. Many industries face challenges in finding workers with the necessary expertise.

- Integration Issues: Integrating automated systems into existing processes can be complex, requiring careful planning and sometimes significant restructuring of workflows.

- Maintenance and Downtime: Automated systems require regular maintenance to ensure they operate efficiently. Unplanned downtime can be costly, especially in industries where continuous operation is crucial.

SSC Works: Maintenance Services for Automated Systems in Mining

At SSC Works, we understand the importance of keeping your automated mechanical systems in top condition. Our team of expert technicians specializes in maintaining heavy equipment used in the mining and construction industries. Whether it’s automated drilling machines, conveyor systems, or transport vehicles, we ensure that your equipment runs efficiently and with minimal downtime.

Our comprehensive maintenance solutions include diagnostics, repair, and system upgrades, all aimed at optimizing the performance of your automated mechanical systems. Trust SSC Works to provide expert service that will enhance your productivity and keep your operations running smoothly.

Have you implemented automated mechanical systems in your industry? What challenges have you faced, and how have these systems improved your operations? Share your thoughts and experiences in the comments below!