Heavy Machinery Repair and Custom Components

Heavy Machinery Repair and Custom Components: Your Trusted Solution

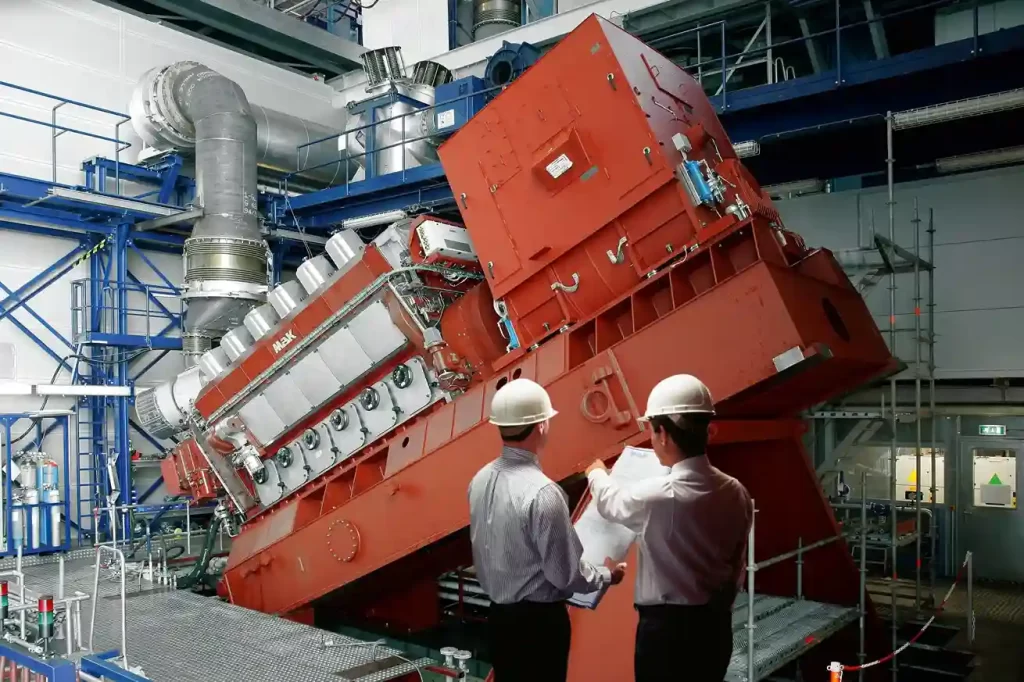

The heavy machinery industry is one of the most challenging sectors. Vehicles and machinery used in mining, construction, and other industrial fields must always be in peak condition to ensure productivity and safety. One keyword that often comes up in this industry is heavy machinery, which covers a wide range of machines such as excavators, bulldozers, and dump trucks, all the way to more complex components like train or ship engines.

However, as time goes on, these machines inevitably experience technical issues that require prompt attention. One of the best solutions to maintain heavy machinery’s performance is by conducting repairs in a timely and thorough manner, often involving the production of custom components to replace worn-out or damaged parts.

Types of Heavy Machinery Repairs

Repairing heavy machinery is not just about fixing broken machines or components but also involves creating custom components tailored to specific machinery requirements. This is often necessary in large-scale equipment operating in harsh environments, such as mines or construction sites.

Common repairs and custom component production for heavy machinery include:

Rebuilding Engines and Components

Engines and engine components such as transmissions, hydraulic systems, and electrical systems on heavy machinery often experience wear or degradation over time. The rebuild or overhaul process allows replacing the worn parts without needing to replace the entire engine.Creating Custom Components

Not all heavy machinery uses mass-produced components. Some machinery requires specific components that can only be produced through custom designs. These custom components include parts like cutting blades, hydraulic pumps, and even structural elements of the machinery itself.Hydraulic System Repairs

Hydraulic systems are crucial for the proper functioning of many types of heavy machinery. If the system fails, it can lead to significant performance losses. SSC Works has expertise in repairing and maintaining hydraulic systems for various types of heavy machinery, both for local repairs and mass-scale solutions.

Common Incidents in the Field

In reality, incidents related to heavy machinery failures are common on the field, which can hinder productivity and increase operational costs. Some of the common incidents include:

Hydraulic System Leaks

Leaks in the hydraulic system are a frequent cause of heavy machinery failure. These leaks often occur due to worn components or damage to hoses and fittings. If not repaired promptly, it can lead to operational failures and further damage.Engine and Component Failures

Engine or component failures, such as those affecting pumps, compressors, or other parts, can result in significant downtime. These failures often stem from either inadequate maintenance or damage caused by external factors such as collisions or extreme work conditions.Clogging in the Exhaust System

Exhaust systems on heavy machinery, particularly diesel engine vehicles, are vulnerable to clogging. This is typically caused by the accumulation of dirt, dust, or other foreign materials. If not addressed quickly, this can lead to serious damage.

Initial Handling of Incidents

Every incident on the field must be addressed with the right steps to minimize further damage. Some initial actions include:

Turn Off the Engine Immediately

The first step is to switch off the engine to stop any further damage. Ensure that the electrical and hydraulic sources are disconnected to prevent more significant problems.Inspect Relevant Components

Check the suspected damaged or leaking components, such as the hydraulic system, electrical wiring, or the main engine. Understanding the issue at hand will help proceed with the repairs effectively.Call a Professional

For more complex damage, contact a technician or a heavy machinery repair company with experience in handling similar problems. SSC Works, with its expertise and knowledge, is ready to provide accurate and efficient solutions.

SSC Works Solutions

If you’re facing issues with heavy machinery or other equipment, SSC Works is here to assist. With years of experience in heavy machinery repairs and custom component manufacturing, we offer the right solutions to get your machinery back to optimal performance. Whether your need is for a single part or large-scale production, we can handle it all.

With SSC Works, you gain:

Guaranteed Quality

We only use the best materials and the latest technology to ensure your machinery operates at maximum efficiency.Professional Team

Our technicians are specially trained and have years of experience dealing with heavy machinery repairs.Timely Solutions

We prioritize speed in handling your issues to minimize any downtime.

Contact Us Now

If you need help with heavy machinery repairs or custom components, don’t hesitate to reach out to SSC Works at our WhatsApp [wa.me/628113511097]. We are ready to provide you with the best solutions for your heavy equipment needs!